Children's eyes light up when a tractor drives past. And what luck for those who get to ride along or even sit in the driver's seat! Many adults also get excited about the large agricultural machines. Fendt tractors are popular in many countries around the world. Florian Hammel is responsible for strategic plant and technology development at the Fendt plant in Asbach-Bäumenheim, Bavaria. He is proud to work for the brand and is pleased “that every green part you see on a Fendt tractor comes from this factory.”

Hammel and the sheet metal processing team manufacture, among other things, the sheet metal for the outer surface of the cab and hoods of the large tractors. Previously, a laser flatbed machine with a conventional plate changer cut the contours from the sheets. But at some point that became too slow for Florian Hammel and the team: customer demand increased significantly, but storage capacity in the production area did not. "It was clear that we would not be expanding the factory premises. And so it was clear that we had to find a solution with more output in the same space,” he explains.

It's faster with coil loading

Oliver Müllerschön is the expert for so-called laser blanking at TRUMPF. In this process, the system unwinds the sheet metal strip directly from the coil, i.e. a sheet metal roll, and feeds it to the laser cutting machine. "Customers need this when laser cutting isn't productive enough for them. And this is exactly what Fendt needed. We were quickly able to convince our colleagues at Fendt of the benefits of our new TruLaser 8000 Coil Edition.

But before the Fendt site in Asbach-Bäumenheim accepted the offer, Florian Hammel sat down with his team and calculated everything in detail. The first parameter: the time required for the pallet changes. The processed sheet is removed from the laser cutting machine and a new one is inserted. “This step is of course not needed if we simply unwind a long coil.” So how much time is saved in total? „Around 600 work hours per year. We can then use this time more productively,” says Hammel. “Overall, the total production time of the laser system increases by around 14 percent.”

More components per meter of sheet metal thanks to laser blanking

That's already impressive, but Müllerschön pointed out another aspect: “A sheet is a maximum of three or four meters long. There is therefore only limited space for larger components and the scraps are thrown away." The situation is different when cutting directly from the coil: “The sheet is virtually infinite. It is possible to nest the parts into each other much better. In other words, you get more components per purchased meter of sheet metal." Hammel also wanted to know exactly what the difference was here and used his real contours to calculate the difference between sheet and coil production: “About 20 percent less material for the same result! What's more, the purchase price of the coils is also lower than that of pre-pulped goods,” says the Fendt planner.

Swap storage trips for crane lifts

But even the longest coil comes to an end. and a new one needs to be loaded. Just like pallets with sheet metal. But with stacks, more storage travel cycles are needed per day. Here, too, Hammel considered what the new TruLaser 8000 Coil Edition would mean for his work processes: “We move the sheet stacks from the truck into the store, out into production when needed, to the machine and so on. That's a total of five storage travel cycles per provision." And with the coil? "One crane lift cycle. So we swap five forklift trips for one crane lift from the truck into the laser blanking system. This eliminates around 2,400 storage trips per year." His calculations convinced him and the Fendt site in Asbach-Bäumenheim opted for the laser blanking system.

Conversion to coil - paid off in no time

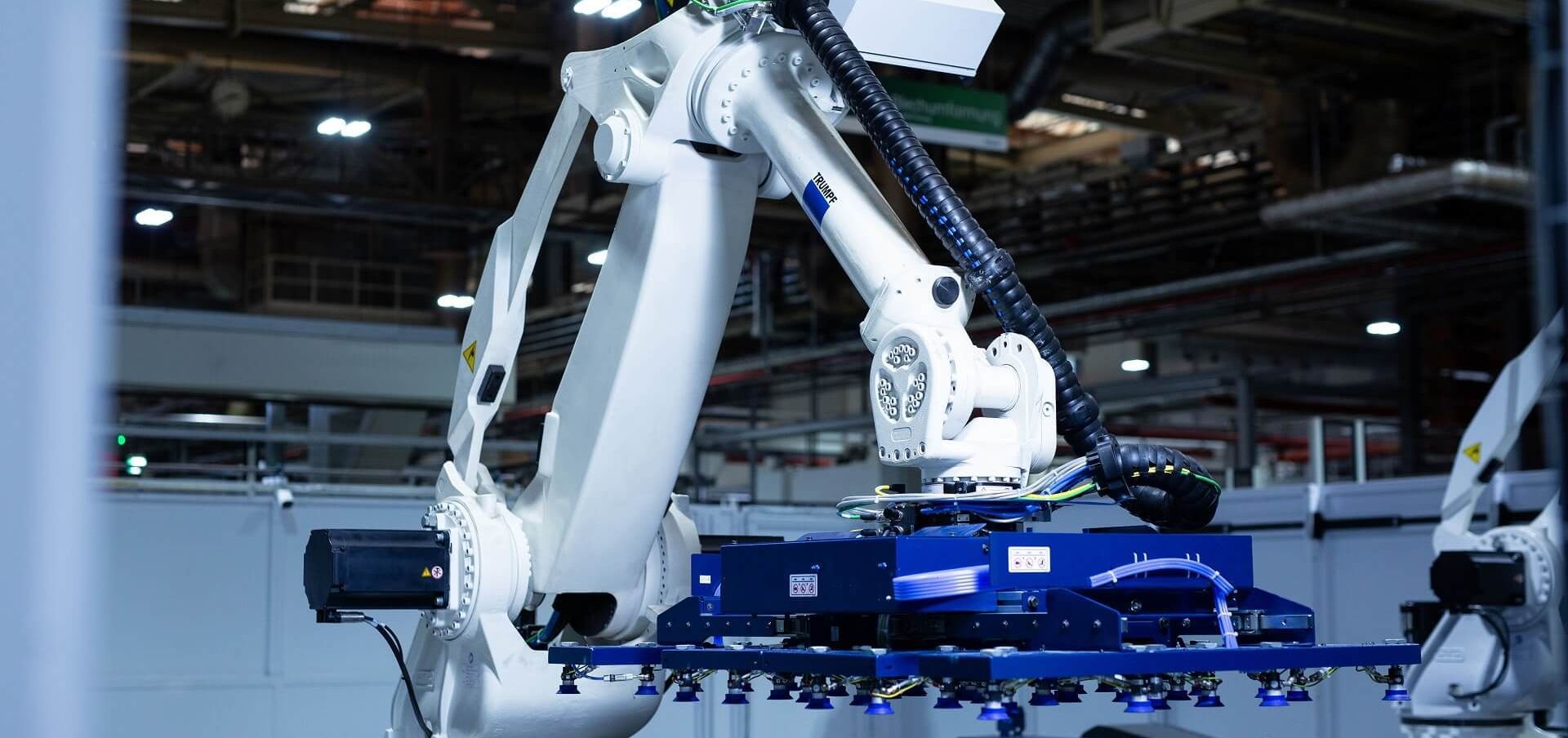

Then the time came: the first truck loaded with coils drives into the Fendt plant for the first time. The overhead crane loads the TruLaser 8000 Coil Edition. The sheet metal unwinds and is pulled into the cutting chamber. Here the laser cutting head zooms across the sheet, applying the contours. Downstream of the cutting chamber, two discharging robots remove the components from the coil strip and carefully place them down. The small amount of scrap is automatically transported to a container outside. The part production process continues. Florian Hammel is happy: "The nesting process ensures we use the sheet efficiently. And we have increased our output but with less work. And thanks to all of this, the laser blanking system paid for itself very quickly." Hammel says, grinning. "Of course, I won't be saying exactly how quickly. But we worked that out as well, and it really is fast."