Prutting, near Rosenheim, nestles picturesquely in the green countryside of southern Bavaria, between lakes and mountains. It is here that the company BBW Lasertechnik uses high-end lasers and beam shaping to manufacture products that help pioneering technologies achieve their breakthrough. Andreas Bürger, joint managing director of BBW, has a simple formula to express the company philosophy: “We just make sure we’ve got the latest laser tech, and the rest follows from that.” By this, he means orders, research projects, and designs for machines and complex products–in other words, everything that makes BBW stand out from the pool of contract manufacturers that offer laser processing. Anyone curious as to the latest market trends need do no more than take a look at what the company and its 200-strong workforce is currently up to.

BATTERIES FOR E-MOBILITY

When the battery boom first began, Andreas Bürger conducted a mental inventory. “We looked at all our machinery and all the know-how we have here, and we quickly realized that we were perfectly set up to produce battery modules and energy storage systems.” While others would need to buy new machines and bring in new expertise, BBW already had everything in place. “Our company motto has always been that we aim to give customers something new before they’ve even asked for it.”

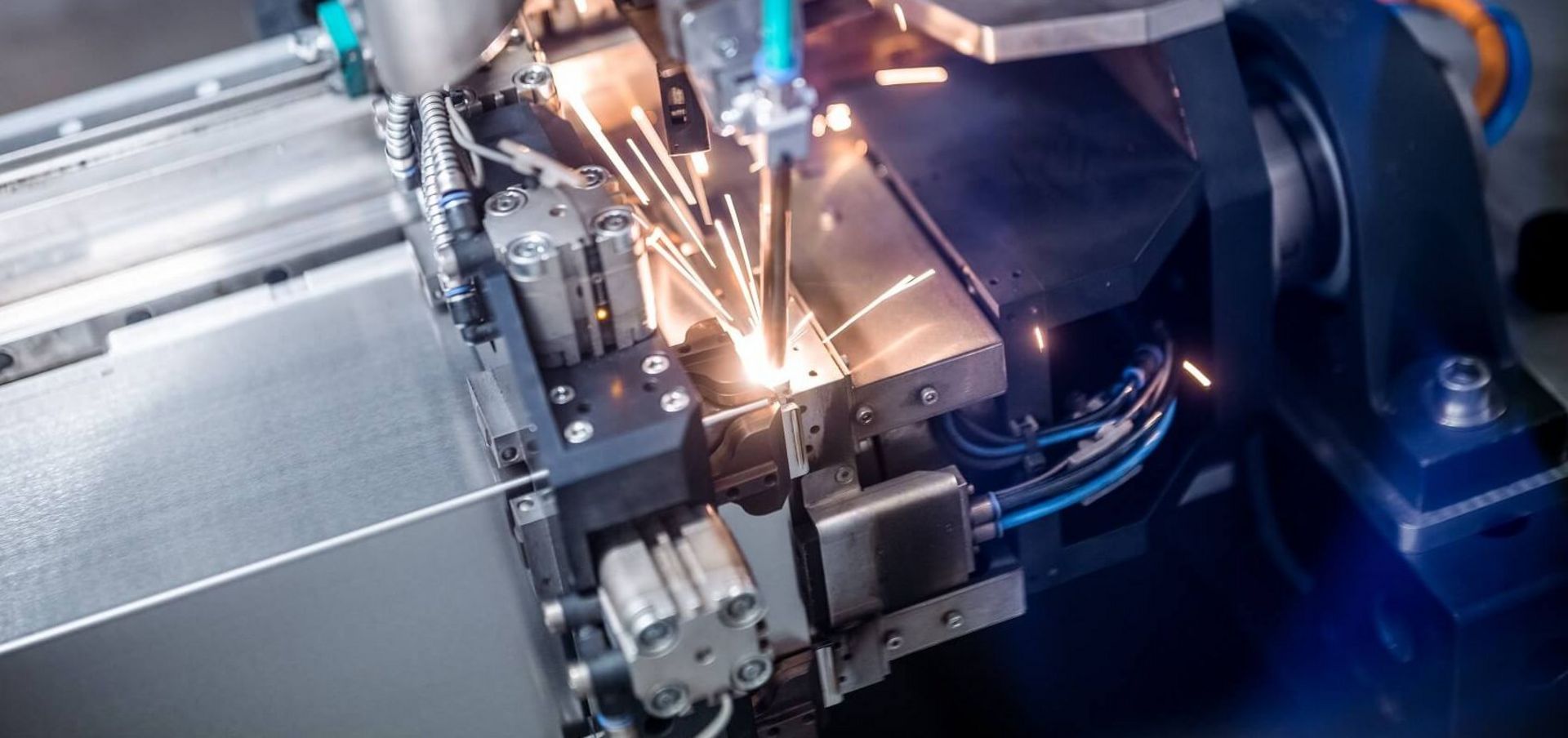

Underlying this offer is BBW’s experience in manufacturing highly complex assemblies and its knowledge of all the various strategies for processing even the most difficult of materials. Whenever things seem to reach an impasse, that’s when the company starts to research and develop new approaches and techniques. “We look for the niche in a boom market,” he explains. “That’s really paid off with batteries for electric vehicles. The cells are incredibly sensitive, so the parameters are very tight when it comes to welding the cell contacting system. And different types of cells require different laser sources and processes.” Battery modules now account for almost 40 percent of BBW’s manufacturing output. But that’s not the company’s only high-end niche market.

EXPERTISE FOR AEROSPACE

At its plant in Prutting, the company has some 50 laser machines for welding, drilling, ablating, texturing, precision cutting, and cleaning, all spread across various production halls. According to Bürger, however, there are customers who expect more than just a big machine park. “We operate in some highly complex industries–battery production, medical technology, electronics for the semiconductor industry, and aerospace,” he explains. “So we have to find other ways of convincing our customers.” That’s why the company has its own development department and metallography department–that and the Bürger family’s own insatiable interest in laser processing. At the start of each project, the company conducts an in-depth feasibility study and preliminary tests in its own lab.

In many cases, BBW will take on a number of laserprocessing steps and also do the post-processing or even manufacture complete assemblies. “We like to do things ourselves. That way, we can be sure that it will all work perfectly in the end.” In the highly demanding, highly specialized markets that BBW serves, that’s a vital consideration. Certification for the aerospace industry, in particular, is not easy to obtain. “In some cases, every weld seam is x-rayed. We have to train our workforce accordingly and document this in full. But it’s all worthwhile, if the quality’s right.” To ensure that such high standards can be met, the company also has its very own engineering department. Many of the company’s laser systems are made in Prutting, with the laser source bought in, but the machine itself designed and built in-house. “And if today’s technology places a limit on what we want to do, that’s when we start researching.”

PLUS: LASER RESEARCH

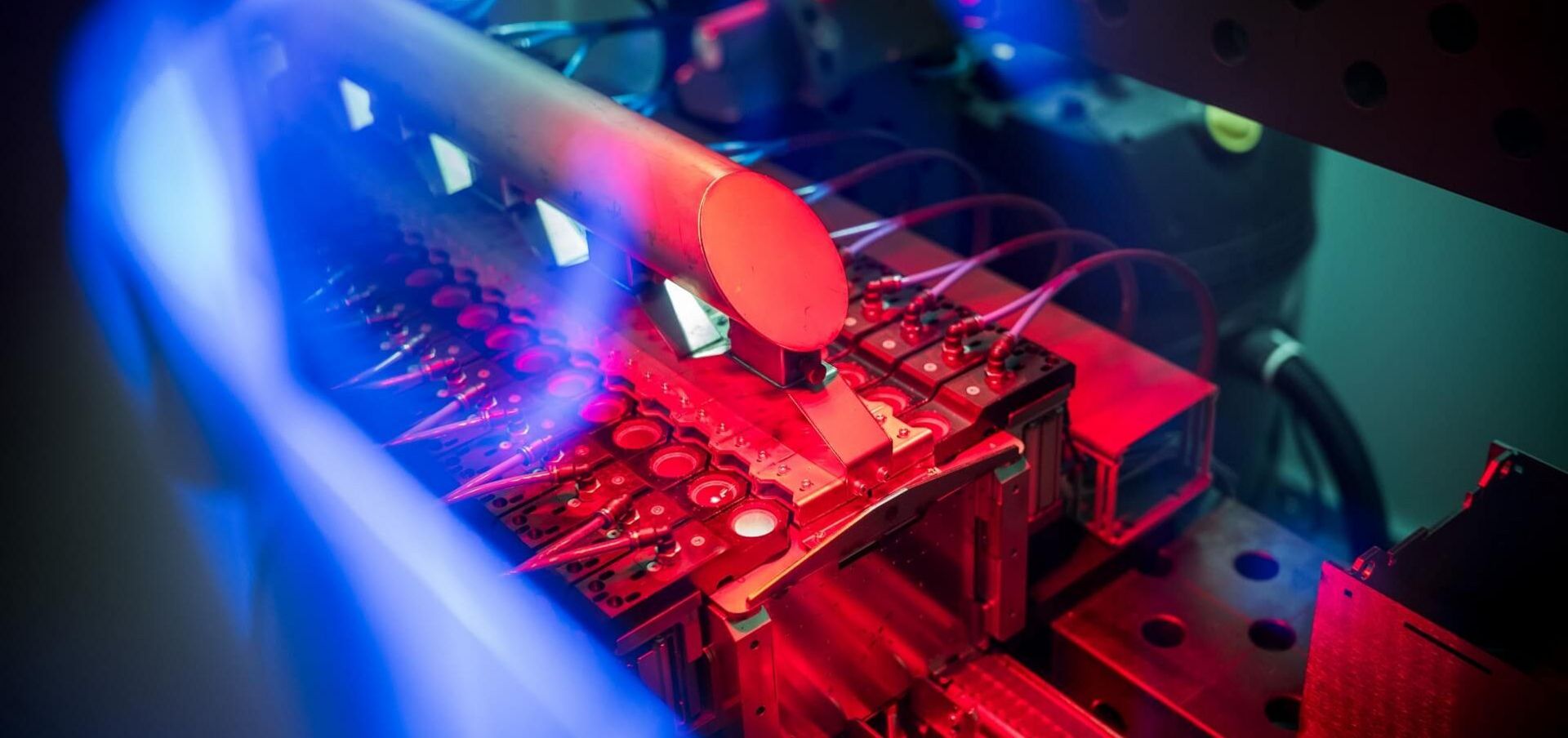

Because it’s impossible to develop everything in-house, BBW also collaborates on international research projects. As part of the LaserComposite research project, funded by a German government innovation program for SMEs, the company looked into the use of green and infrared lasers for welding aluminum-copper hybrid joints. BBW was able to show that this method largely prevents the two metals from mixing in the seam to form unwanted intermetallic phases–i.e., alloys. In another–inhouse–development project by the name of Weldshape, the company tackled the problem of hot cracks that arise when welding the aluminum alloy AW6060, which is highly prone to this issue. The solution is to use dynamic beam shaping in a process based on a self-constructed laser system featuring a 16 kW single-mode laser and high-end scanner.

Beam shaping? Correct. BBW is at the very cutting edge of laser processing. Beam shaping is naturally part of that mix. As Bürger explains, of the 50 or so laser systems in operation at BBW, a number of them are earmarked for developing this technology. “There’s a lot riding on beam shaping. It provides a way of dealing with a number of thorny issues, such as ensuring that the weld pool remains stable during laser welding. At BBW, what we really need is variable beam shaping. That’s because fixed optics are not economical for the small batches that we produce for our niche markets.”

In other words, it’s only when the optics can be individually adjusted for each batch that it becomes worthwhile for BBW. “So we’re looking closely at how we can make best use of this technology. Apart from us, as far as I know, there’s no other laser welder with a beam shaper on the premises. At the end of the day, however, that won’t make any difference if we can’t provide a clean and proper production environment. As well as investing in the development of technology, we also need to ensure that we have the right setup for manufacturing, and that includes cleanroom and material analysis facilities. But all of that goes hand in hand here.”