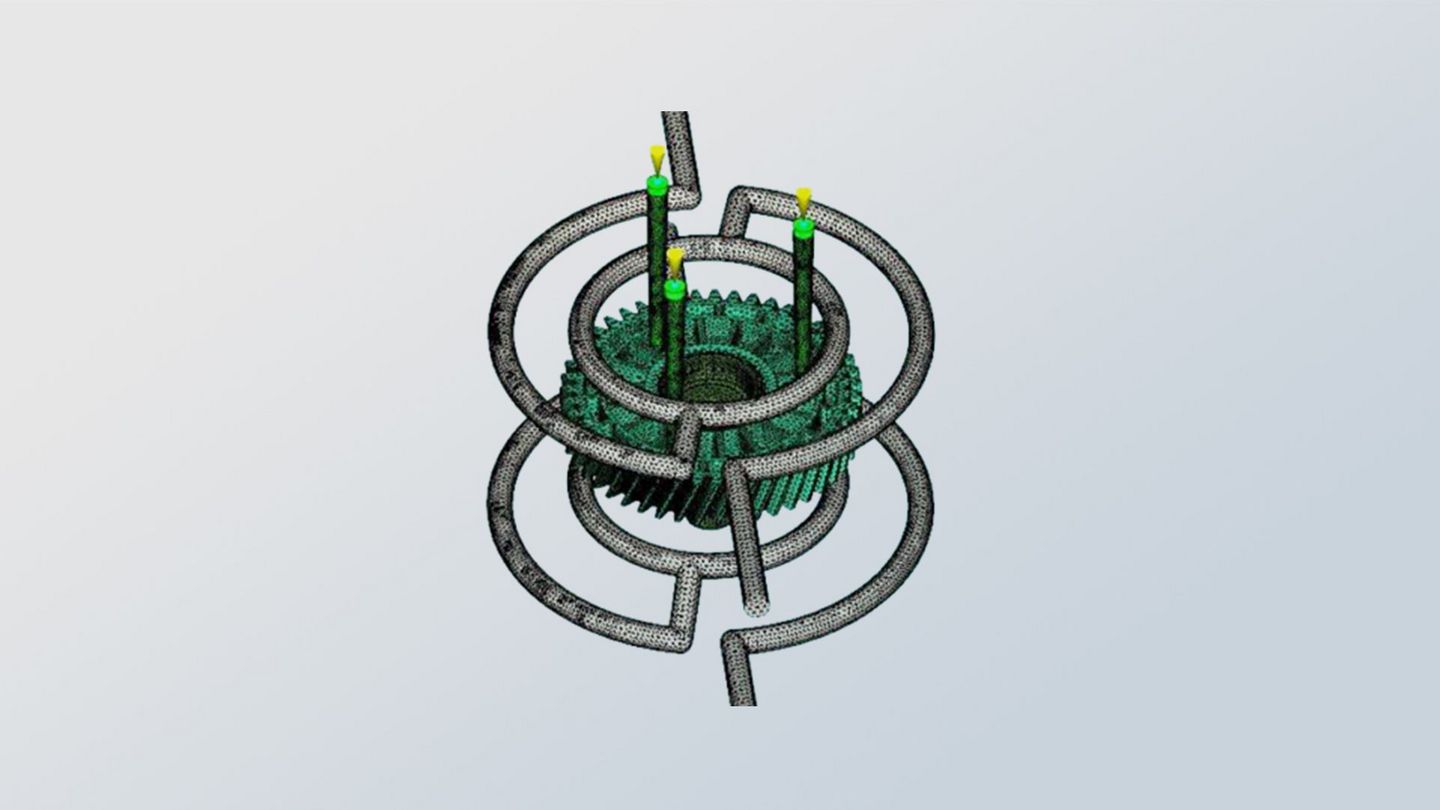

Conformally cooled insert for high-precision gearwheel

Thanks to the AM-compliant design and the associated integration of conformal cooling channels, the tool insert made of tool steel (H11 or 1.2343) was able to significantly improve the stability and the process window during injection molding. Now, high-precision POM (polyoxymethylene) gearwheels can be mass-produced with minimum rejects and maximum safety. The conformally cooled insert significantly reduces the cycle time. The technical as well as economic goals have been achieved with additive manufacturing. Tool steel H11 or 1.2343 can be reliably processed by using the TruPrint 5000 with preheating to 500 °C.

Crack-free tool inserts

Density > 99.9%

Cycle time reduction > 20%

Facts & figures about the example part

Material: 1.2343 / H11

Weight: 1,270 g

Build time: 17.3h (for 7 parts)

Number of layers: 9

Created by: IMS Gear SE & Co. KGaA

Find out more about the product

Contact