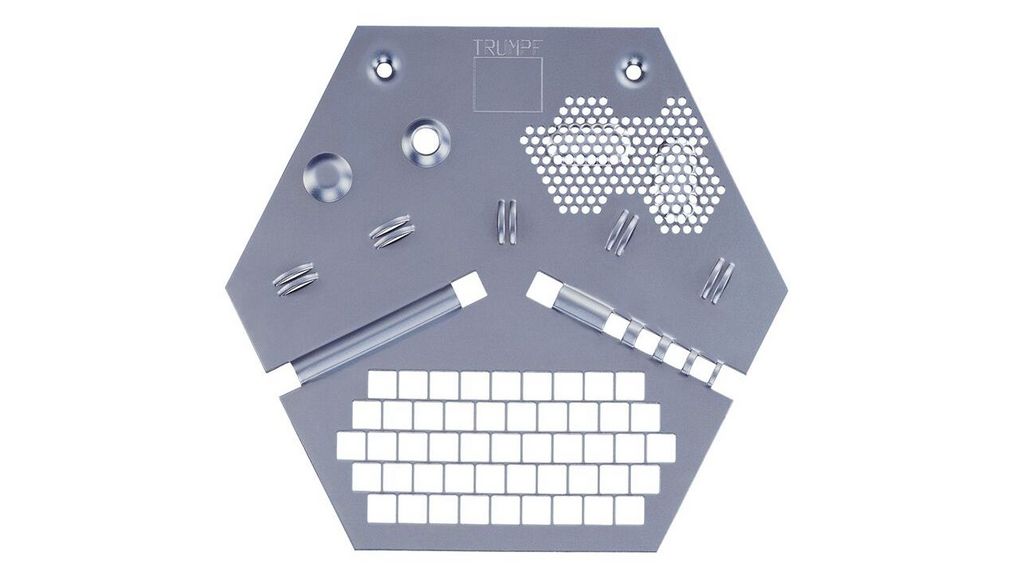

Only a punching machine can achieve geometrically precise shapes to the highest levels of quality – with no needle holes or spatter, no waves or scratches. This means, for example, that you can create a perfectly round circle or a perfect square.

The advantages of our TRUMPF punching machines

Punching with TRUMPF is far more than perforating sheets and metal

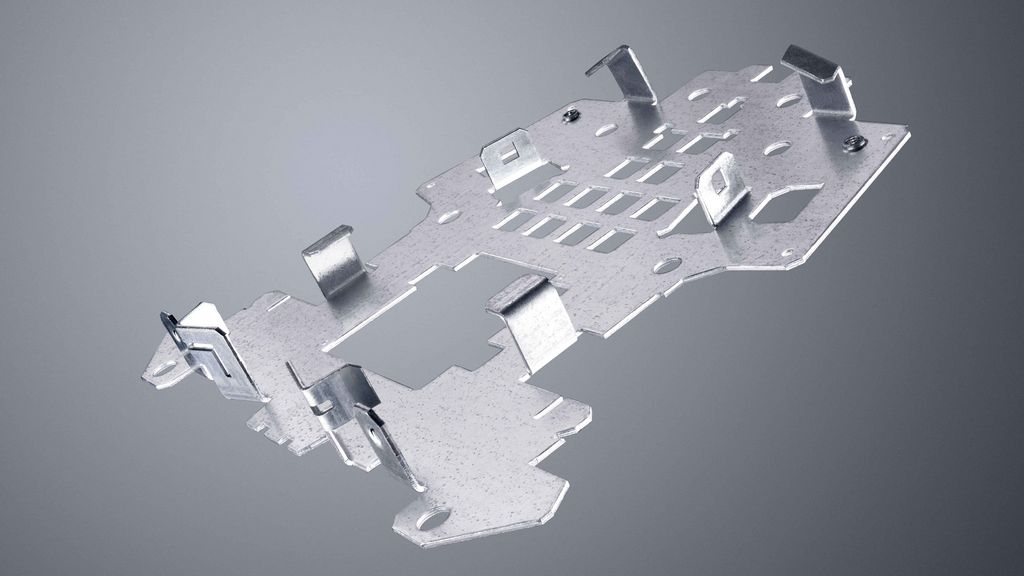

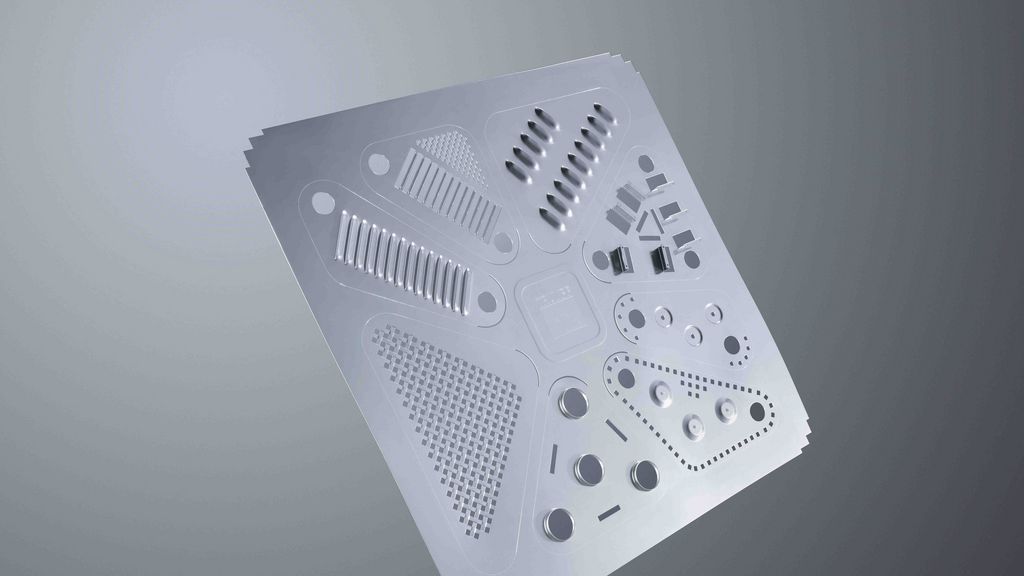

Metal punching, slitting, forming, countersinking, rolling, marking, deburring and tapping: you can manufacture complete metal components on a TRUMPF punching machine. The technology is versatile due to the abundance of punching tools. There is basically no punching burr with today's CNC punching processes. Sorting and removal is also easier than ever with TRUMPF thanks to a variety of automation solutions. Punching proves to be a real time-saving technology for many applications – use TRUMPF punching machines for specific applications to ensure the future success of your company.

1. Geometrically perfect shapes

2. Versatile parts processing

3. Quick, quicker, punching

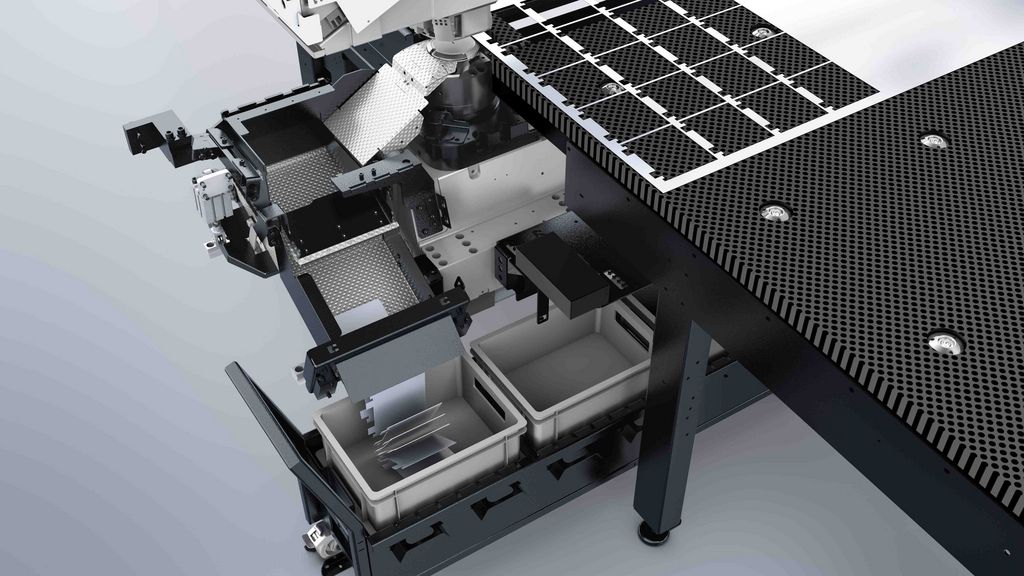

4. Clever concept

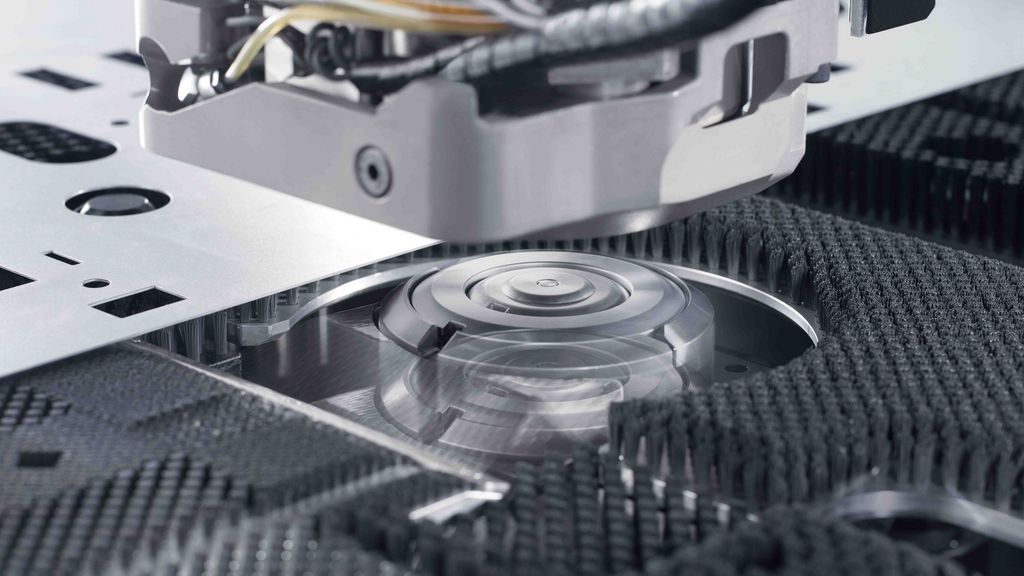

5. Safe processes

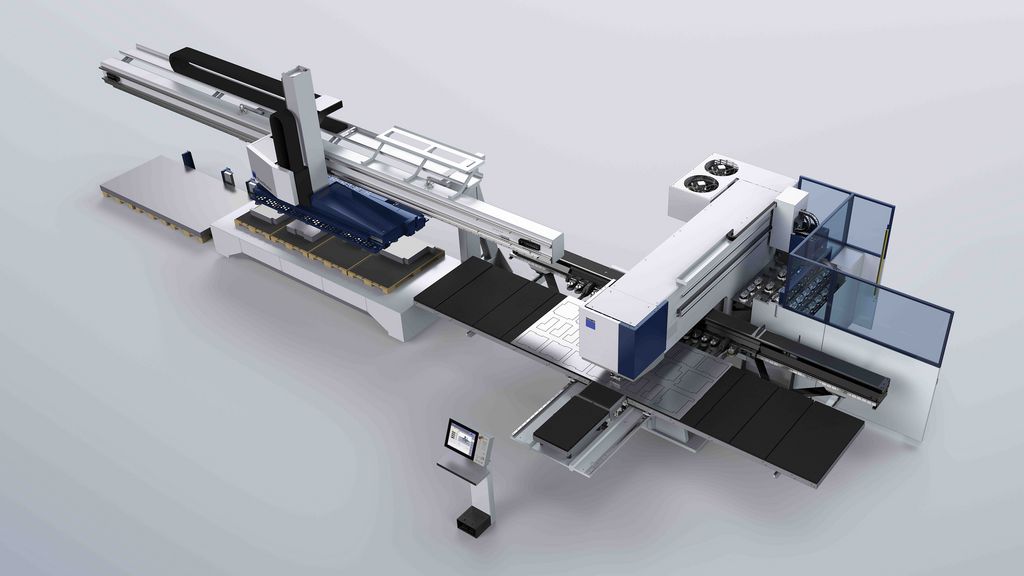

6. Make more automatically

Classic example: perforated sheet

A classic processing example are perforated sheets: here punching machines outperform all other technologies in terms of speed and cost-effectiveness. Find out for yourself!

Example: perforated sheet with 15,510 holes, medium sheet size: 2,500 x 1,250 mm, sheet thickness: 1 mm, bore hole diameter: 8 mm

Result: you save 76 % processing time with a single tool, and as much as 95 % processing time with a cluster tool!

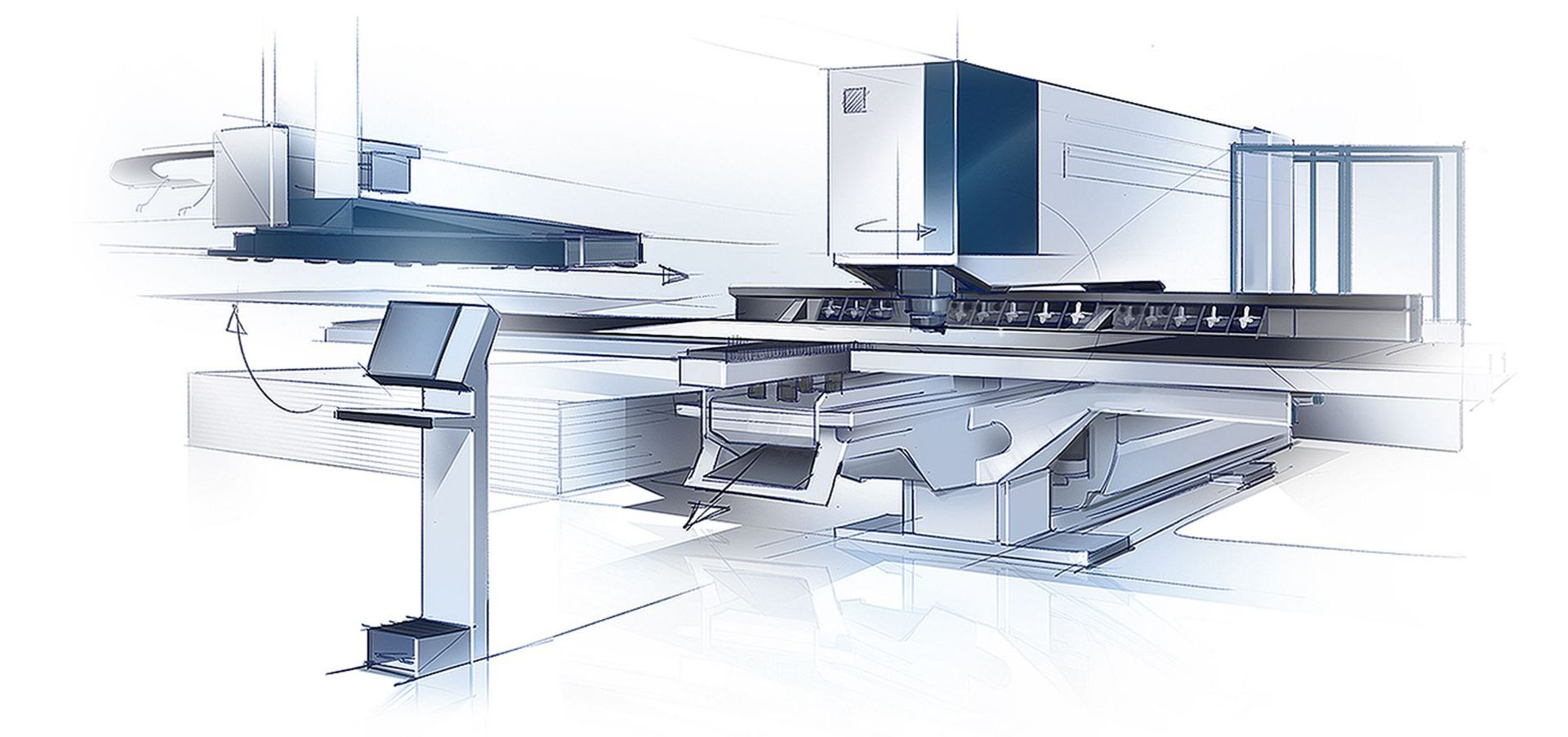

The right machine for your success

From setting up to punching to removing your parts, TruPunch machines are built down to the smallest detail to maximize your utilization. The result: highly precise and scratch-free parts – you can rely on that one hundred per cent even after many years of use. From the TruPunch 1000 entry-level machine to the high-end TruPunch 5000 productive machine, you will find the right machine for your application with us.