TRUMPF Smart Factory in Ditzingen

Your solution starts here - with a reliable partner at your side!

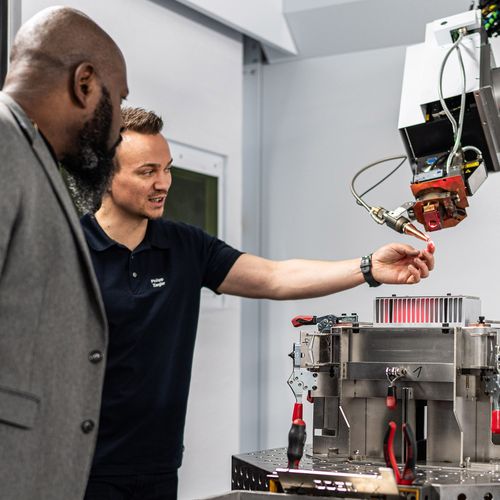

Whether you are a small family business or a medium-sized company - the TRUMPF Customer Center focuses on you and your challenges. Our experts analyze your needs and work with you to develop tailor-made solutions for your metal processing. We support you not just today, but in the long term: with innovative technologies, reliable service and personal support.

Arrange your appointment now and see for yourself how we can make your production future-proof!

In numbers: the Smart Factory in Ditzingen

Experience the future of your production - with us today!

In our Smart Factory in Ditzingen, you can experience how people and machines work hand in hand. Intelligent systems ensure flexible, efficient and transparent production that directly advances your production.

Benefit from automated processes that shorten your throughput times and reduce your employees' workload. Digital assistants help you keep track of orders and stock - anytime and anywhere. Our solutions seamlessly integrate machines - not only from TRUMPF, but also from third-party suppliers - for continuous production without interruptions.

Thanks to intelligent monitoring systems, you can detect faults at an early stage and avoid unplanned downtimes. This increases the utilization of your machines and ensures long-term productive production.

1. Service Center

We always offer our customers the right services for maximum machine performance along the sheet metal process chain. From traditional services (spare parts, customer service, training, etc.) to digital solutions (monitoring, ServiceApp, e-shop, etc.).

2. Application Center

You experience the variety of metal and tubes here. We provide advice for part design in terms of design, production time and cost efficiency. Your options and your production take center stage.

3. Control Center

This is where the various strands come together. All orders are generated, controlled and can be experienced live in action in the Control Center. Oseon facilitates complete transparency and localization of the individual orders throughout the entire shop floor. Put us to the test!

4. FlexCell

The Flex Cell bending automation transforms your manual TruBend 7050 into the fastest bending cell from TRUMPF. When urgent orders are due, you can use Flex Cell to scale your production capacity for simple parts in no time at all. And without the need for additional staff at the machine.

5. Starmatik automation

The unloading automation interface with longitudinal conveyor belt enables the transfer of cut components to any integrator, in this example to the Starmatik automation system. The stand-alone functionalities of the TruLaser Tube 7000 and the good accessibility of the system are retained.

6. Smart material flow

The Sorting Guide provides assistance to the operator directly at the laser cutting machine during the sorting procedure. After removing a part from the sheet, the parts which belong to this order are marked in color in a screen. See for yourself how artificial intelligence increases the efficiency at the interface between the laser cutting machine and the factory flow.

7. TruLaser 3040 BevelCut Edition

The integrated bevel cut transforms this 2D laser cutting system into a versatile standard machine. Thanks to bevel cutting technology, precise geometric shapes can be created directly on the workpiece edge. Bevel angles of up to 50 degrees are possible, and the machine is economical from just 5% bevel cutting. This can save up to 80% of processing time and costs.

8. TruLaser 3030 with SortMaster Vision & SortMaster Station

Cut, sort, done - no programming effort required! Thanks to innovative technology, automatic sorting starts from batch size 1, making manual and time-consuming separation a thing of the past. The third pallet station ensures maximum flexibility and optimized processes, so that efficiency and precision work together perfectly.

9. Autonomous production

Procedural progress, utilization, malfunction – all status data and status information can be called up in real time. It is possible to analyze the entire production with this data to make it easy to detect inefficiencies and bottlenecks. But that's not all! Machines and machine apps actively help the operator process the orders.

10. TruMatic 5000 with storage connection

The processing cell consisting of the TruMatic 5000 with direct storage connection automates the material flow in your punch laser production, from fast loading to unloading, palletizing and sorting. Nozzle changers, pre-separation of sheets parallel to production, the integrated axis for more flexibility, and a variety of individually controllable suction cups allow you to produce autonomously and efficiently.

The following machines can be viewed

Insight into the Smart Factory in Ditzingen