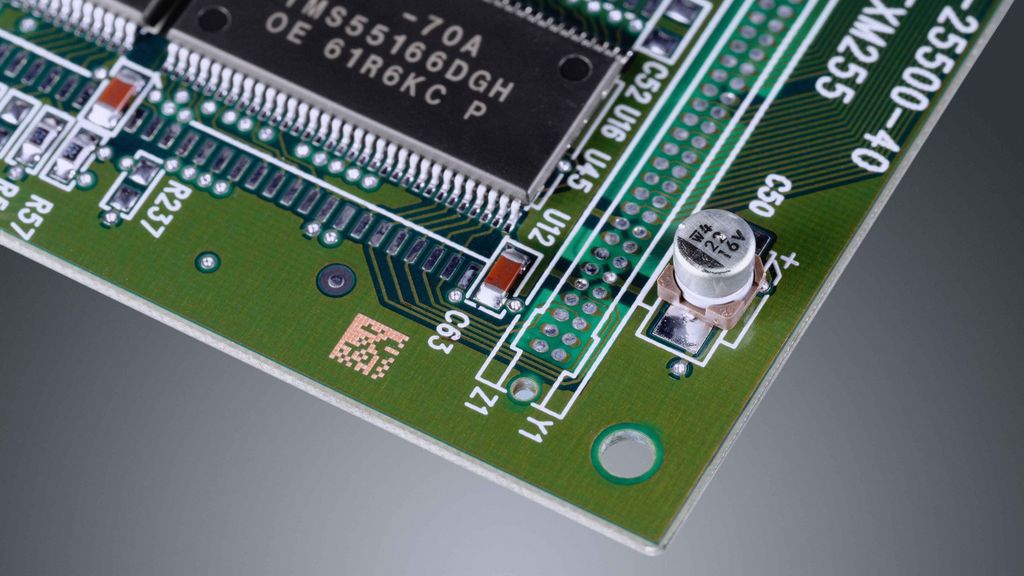

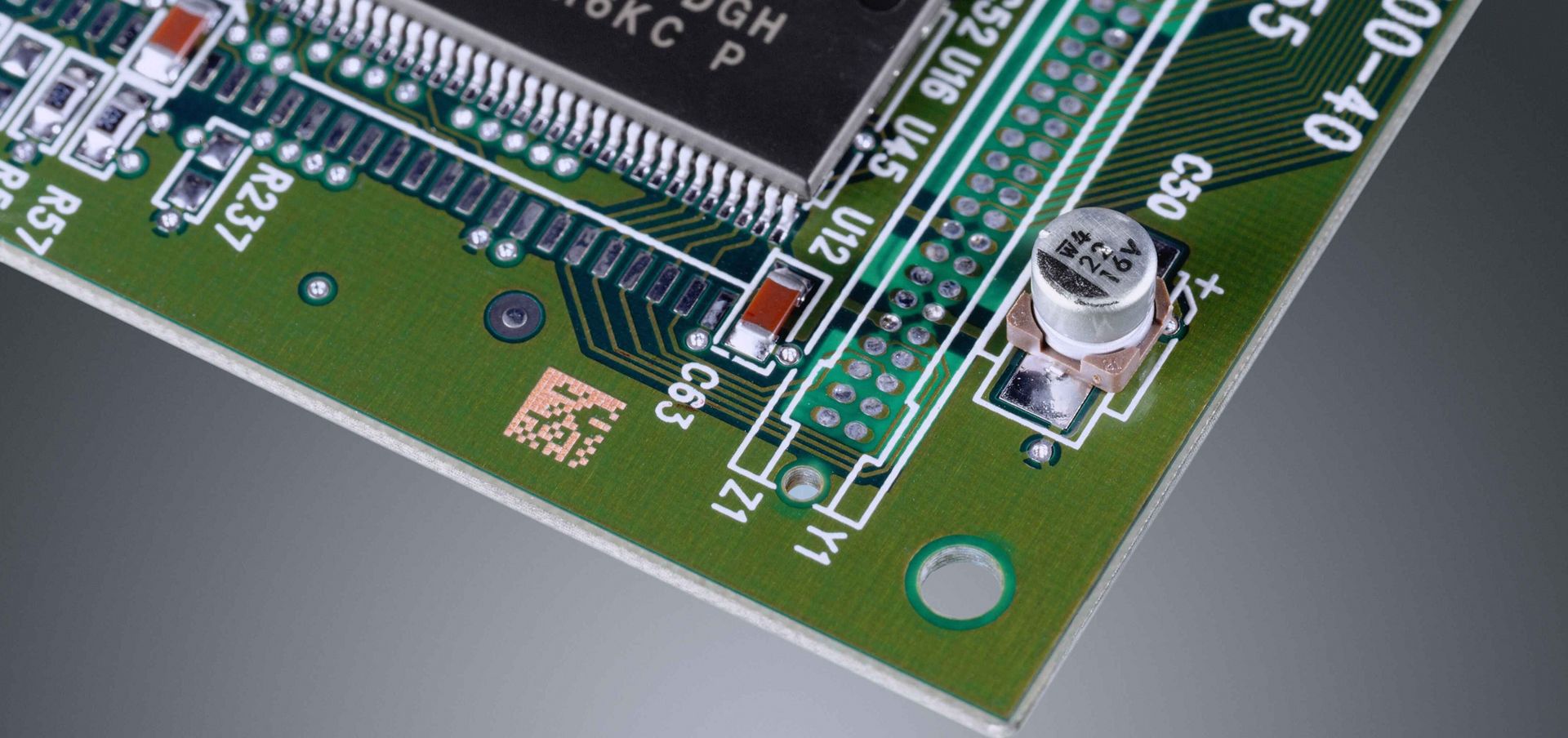

Printed Circuit Boards (PCBs) are built into every electronic product. Their traceability is essential. If a production error should then occur, a complete batch can be quickly identified via their markings. Limited space and sensitive materials require a reliable yet productive process when marking texts, serial numbers, bar codes or data matrix codes on printed circuit boards. Marking lasers from TRUMPF enable reliable and fast laser marking with high peak pulse powers and excellent focusability.

Laser marking of electronic components

Smartphones, PCs, electric cars – a quick glance at our day-to-day lives is enough to know that the electronics industry is huge. And it is growing rapidly. This would be impossible without laser technology. It enables the electronics industry to achieve the efficiency required in production processes. A major role is being played here by the laser marking of electronic components. Productivity is the priority. The laser is just what is needed where the smallest and most sensitive components require permanent markings.

Marking lasers are the preferred tools for marking sensitive electronic components. Process reliability is guaranteed by targeted energy input and stable laser properties – even for different types of component material. The markings must be resistant if the materials are to be exposed to harsh conditions. TRUMPF marking lasers offer flexibility in wavelengths, pulse durations and power classes required for the laser marking of electronic components. They are robust and have high availability. They therefore ensure the electronics industry remains productive.

Marking lasers from TRUMPF significantly reduce processing times.

Marking lasers can also be used to prepare materials for joining by roughening, cleaning and structuring

Laser marking exerts no force on the sensitive electronic components and heat input is low.

The laser enables many different component designs, whether small dimensioned or using different material combinations and intricate connections.