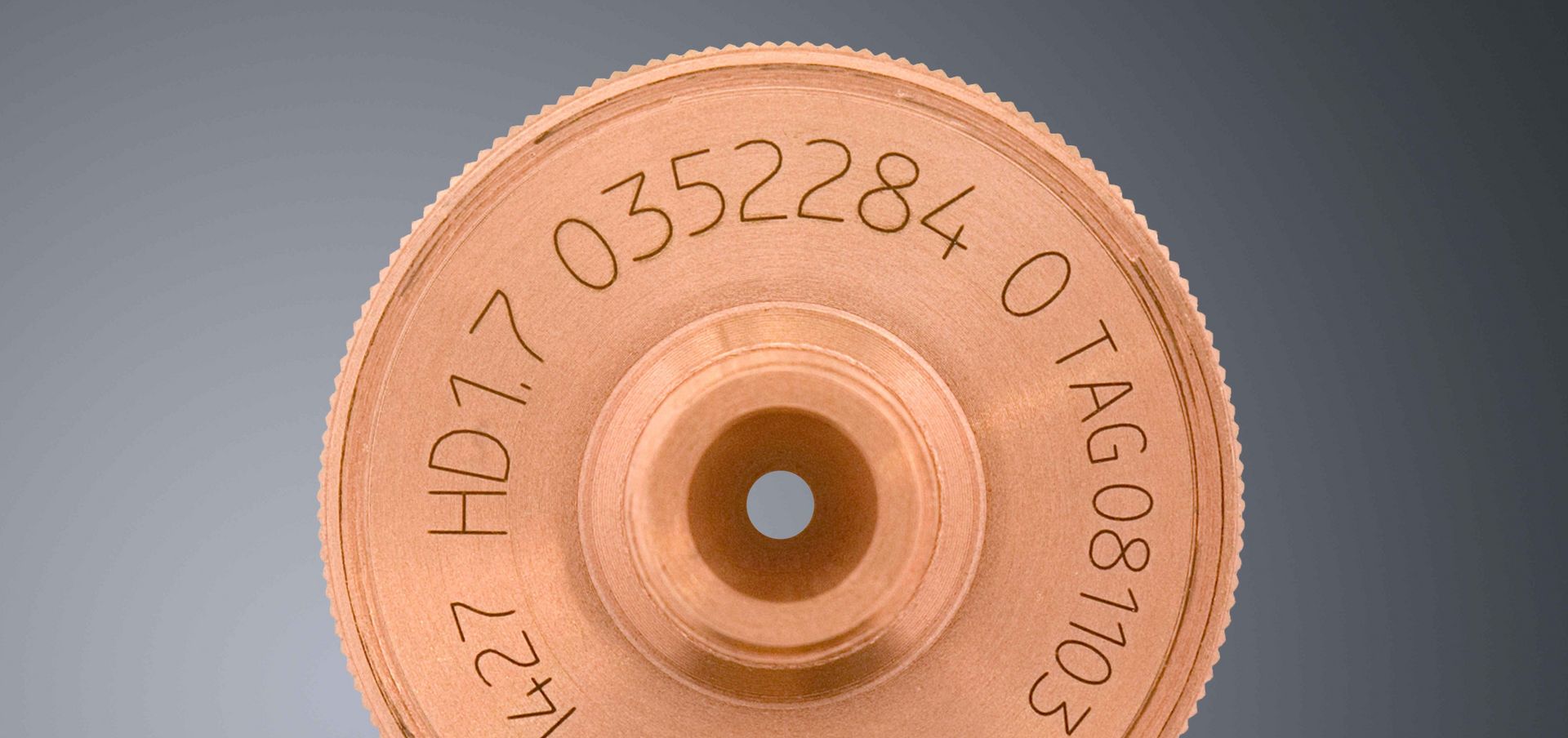

Permanent legibility is essential for serial numbers, labels and logos. To achieve such permanence requires copper components to absorb sufficient light despite the high reflectivity of copper. The desired effect can be obtained by using a laser with high peak pulse power and variable pulse duration. TruMark lasers reliably make markings on copper in a variety of colors and shades.

Laser marking of copper

An industrial sector without copper is unthinkable. The semi-precious metal conducts electricity and heat excellently, is easy to process and durable. But the laser marking of copper presents users with major challenges. Copper's properties make it a challenging material for lasers: it is highly reflective and absorbs very little light. However, users can still benefit from laser marking when applying serial numbers, data matrix codes and other markings to copper components.

Copper's high reflectivity means that it absorbs little laser light. The lasers of many manufacturers are incapable of properly coupling copper components. Achieving the highest quality and durability of markings on copper requires laser power to be focused on a small area. To exceed the process threshold, laser pulses with high peak pulse power are required – as offered by TRUMPF products.

Fine and deep engraving as well as dark markings on copper are all possible using laser

Laser-applied serial numbers, data matrix codes and logos are indestructible.

Component preparation such as cleaning and polishing is performed by the marking laser. This saves time.

Toxic consumables, wear and tear, high energy consumption? Not with the marking laser.