Maximum productivity due to the solid-state laser – even in XXL

With the Trulaser Tube 7000 fiber, the solid-state laser has a broad processing spectrum. The solid-state laser represents fast and flexible processing. Due to RapidCut, the high feed rates of the laser come into their own even on smaller contours. This is a significant productivity advantage, particularly in thinner materials. The open machine concept gives the TruLaser Tube 7000 fiber optimal accessibility during loading and unloading. This means the machine is efficient from a lot size of 1. Due to the Central Link interface, the machine is also optimally equipped for Industry 4.0.

Process parts with a diameter of up to 10 in. and wall thicknesses of up to 0.4 in. for mild steel.

Due to RapidCut, the high feed rates of the solid-state laser come into their own even on smaller contours.

Thanks to its open concept, the TruLaser Tube 7000 fiber offers optimum access.

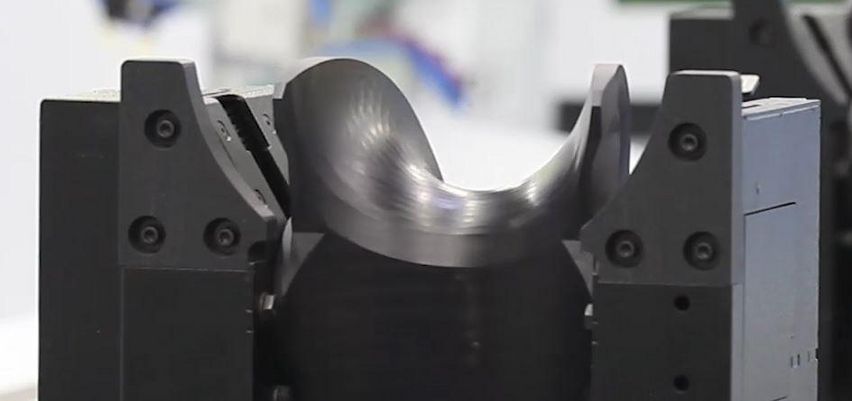

The bevel cutting option enables high-quality bevel cuts of up to 45°.

The TruDisk solid-state laser and high-quality cutting data produce the best possible results.

The state-of-the-art sensor system ensures your entire machining process runs smoothly.

The fully automatic machine settings mean that there is minimal non-productive time when using the TruLaser Tube 7000 fiber.

The TruLaser Tube 7000 fiber can optionally take over further process steps such as tapping threads.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- Value for extended versions (option)

- With automatic loading with LoadMaster Tube 12.5 m, the maximum total weight is 368 kg or 30 kg/m. With manual loading, the maximum total weight is 500 kg or 40 kg/m.