Permanently constant level of hardness, even with complex structures

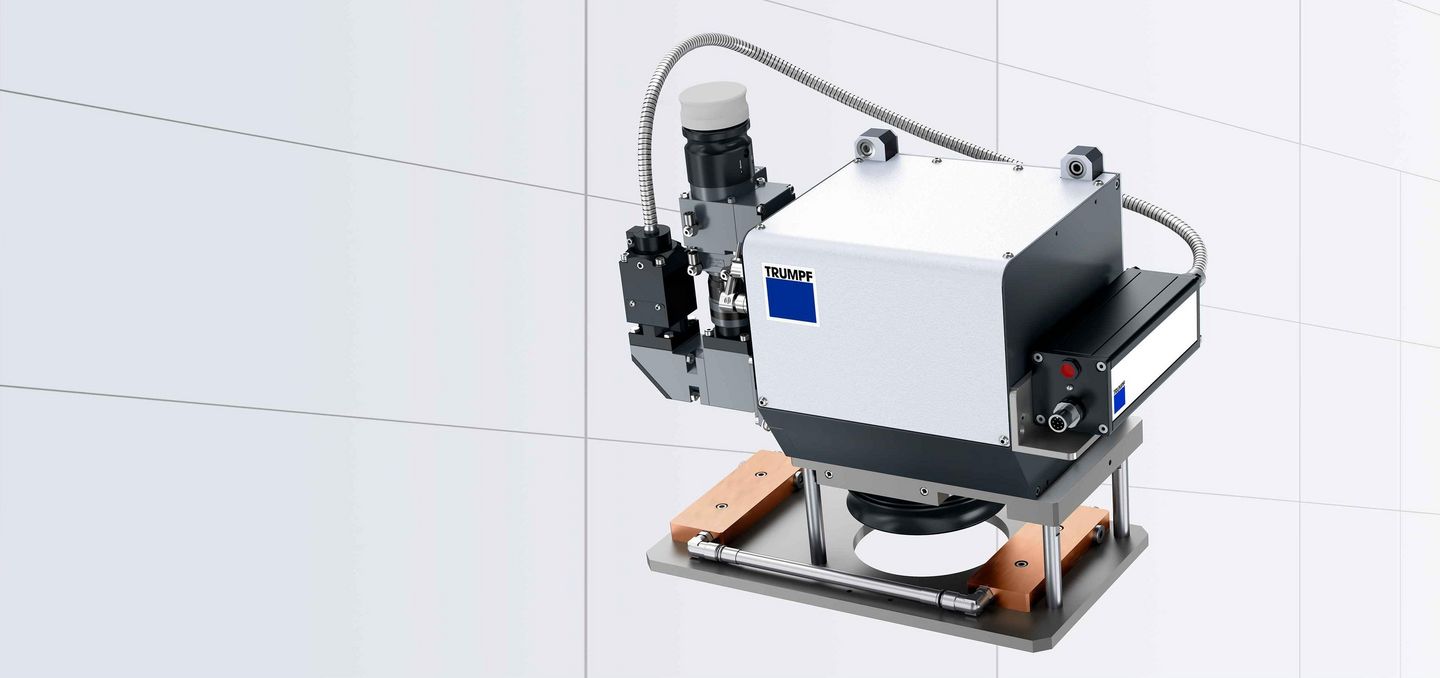

Using the TRUMPF technology package for laser hardening, you can harden surfaces with more flexibility, less distortion, and more uniformity than ever before. The integrated temperature control regulates the laser power independently of location. In this way, there is no build-up of heat along component edges, holes, or in corners, and you can achieve an even hardness depth at a defined degree of hardness. Due to the scanner technology with its own work field, large areas and even difficult component geometries can be hardened with a precise temperature, in a uniform manner. Another plus is that you can document your production processes in a traceable way as a result of the sensor system.

Effectively avoid the build-up of heat at the bends, holes, or corners of a component.

The temperature controller is located directly in the scanner and configuration takes place using the laser control.

You can create the widest range of geometries really easily using the scanner.

As the process is visualized and deviations are reported immediately, you can always keep an eye on quality.

If you harden using the laser, you can reduce the production cycle and shorten the process chain.

Laser hardening saves energy and preserves the environment in comparison to alternative processes.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.