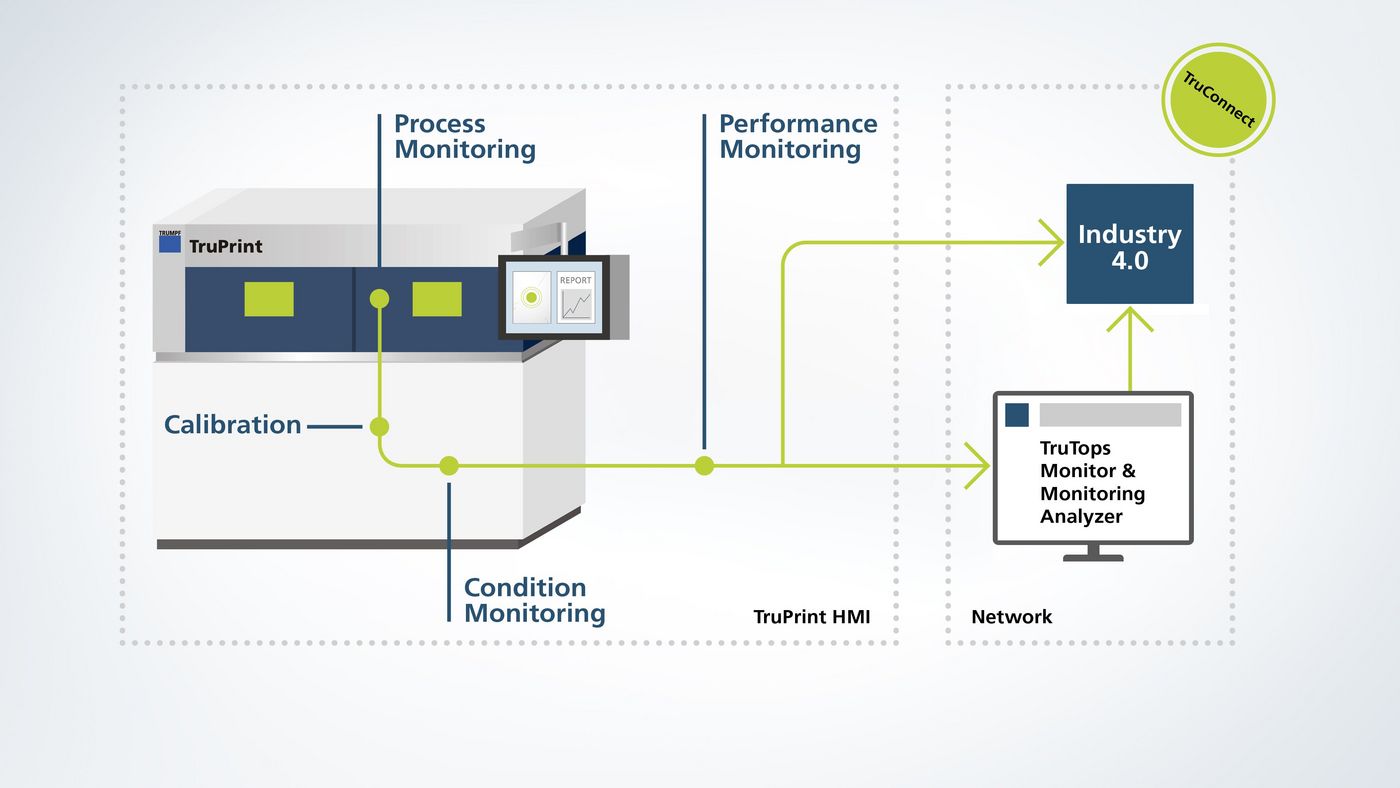

TRUMPF's intelligent monitoring solutions enable you to easily monitor, analyze and calibrate the LMF process in TruPrint machines. You can then produce even more efficiently and achieve higher component quality. The professional monitoring process makes it possible to display and analyze sensor-based data. The offer comprises solutions for monitoring the process, condition, and performance. Monitoring results can be seen directly on the TruPrint machine's HMI or evaluated offline via the Monitoring Analyzer. TruTops Monitor provides not only transparency but also the option for remote access via PC or tablet. Furthermore, an OPC UA interface provides full flexibility to connect to your own software solution. With the additionally available calibration functions, you can check the process-relevant parameters for optimal production conditions before the start of the build job.

TruPrint monitoring

Clever digitization by TRUMPF for your additive manufacturing systems

As a result of the monitoring solutions, you can keep an overview of key production data and system states across all your machinery.

With early error detection and notification, you can react in time.

Due to improved transparency, you can optimize your processes in the long term.

Take advantage of comprehensive information for verifying the quality of your components.

Display and analyze only the key figures that are relevant for your build job.

Process Monitoring for monitoring component quality

Process monitoring focuses on the LMF process. The powder bed is monitored during the laser exposure process. Two products are available for this purpose: Powder Bed Monitoring enables you to monitor the powder bed, and Melt Pool Monitoring enables you to monitor the weld pool of your TruPrint machine. As a result, you maintain full control over the quality of your components – layer-by-layer. Your production system is also made more efficient as errors are identified quickly.

How does Powder Bed Monitoring work?

A central component of process monitoring is the Powder Bed Monitoring function. The integrated camera in the TruPrint machine allows you to automatically monitor the powder bed and images are automatically processed. With this, you have an overview of the component state at all times and can analyze the quality parameters layer-by-layer. The TruPrint machines are equipped with a high-resolution camera system, so you have a precise view of each powder layer. Automatic evaluations are possible in conjunction with the image processing function, whereby the integrated dark field illumination additionally supports the image analysis. As the user, you determine the limit values at which notifications or error messages should appear. As the quality parameters are assigned per layer, locating malfunctions is fast and accurate. This means that you can intervene in the current build job at an early stage. In addition to the powder coating, the Powder Bed Monitoring function also records the state of the layer and identifies protruding parts in the powder bed. The process is ideal for evaluating the condition of the components during the LMF process and for identifying potential developments at an early stage. The automatic corrective recoating option ensures component quality in the event of coating errors. A detected lack of powder is automatically corrected by a new powder coating. After the LMF process, a comprehensive analysis of the individual layers can also be performed via the image selection and be compared with CAD data.

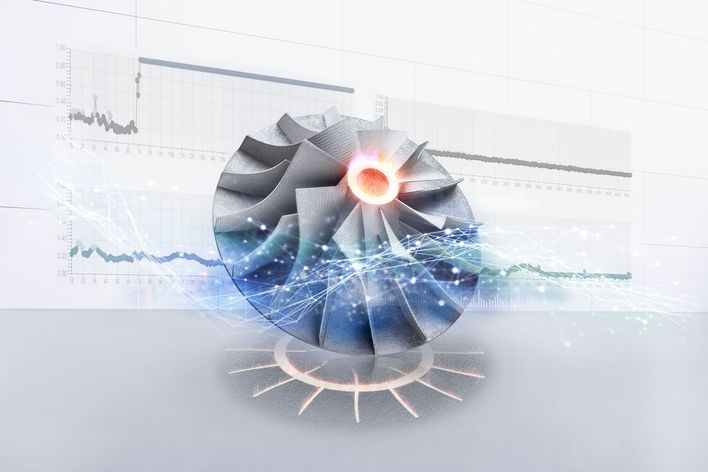

Melt Pool Monitoring – monitoring the weld pool

For a better overview of the LMF process in the TruPrint machine and the ability to optimally evaluate the component quality you can take advantage of the Melt Pool Monitoring product for the TruPrint 2000 and the TruPrint 5000, along with the Powder Bed Monitoring function. With Melt Pool Monitoring, the weld pool of the laser metal fusion process is monitored using sensors. Take advantage of a detailed quality check and documentation, layer-by-layer. This enables you to detect any process deviations early on, including during series production, and, if necessary, see critical areas of the component. These key figures can then be automatically compared with a reference build job to monitor the stability of the process. Furthermore, when using several lasers, you can also easily monitor all of weld pools in parallel. The data can be evaluated on a desktop computer or offline with the Monitoring Analyzer.

Note: This product range and this information may deviate depending on the country. Changes in technology, equipment, price and available accessories are reserved. Please get in touch with your local contact person to find out whether the product is available in your country.