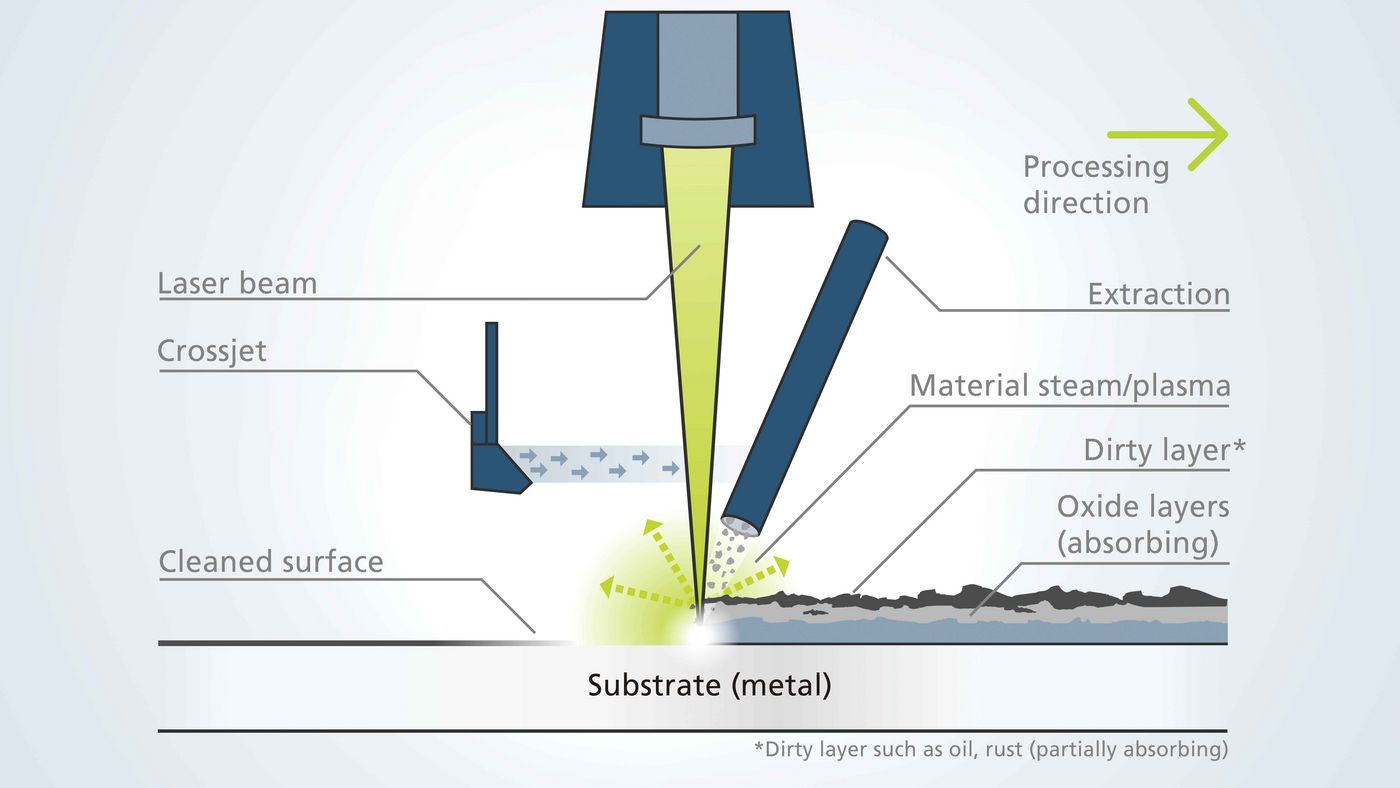

Marking lasers as well as short or ultrashort pulse lasers are used for surface cleaning with lasers.

The operating principle is always the same:

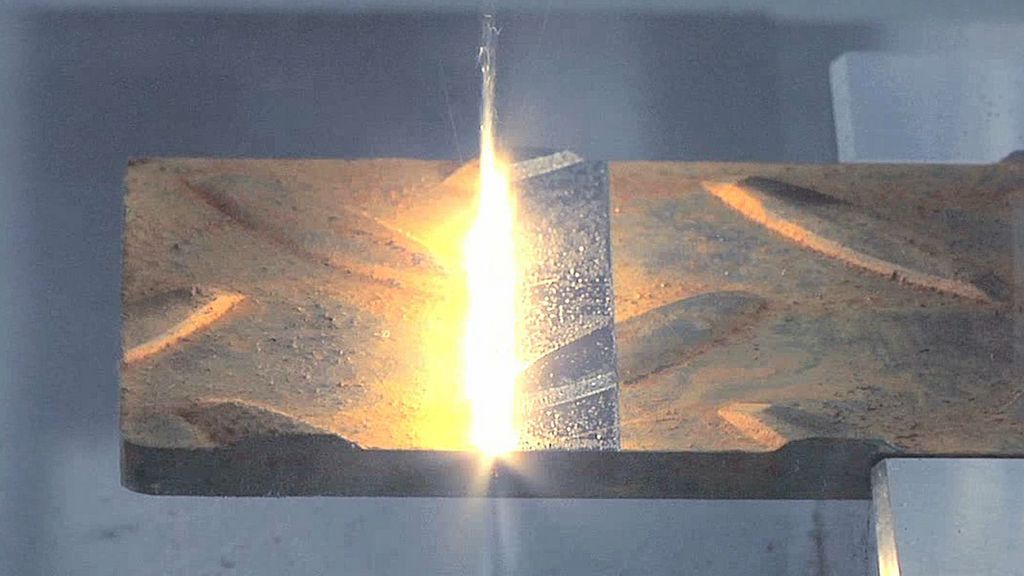

- Pulse by pulse, the focused laser beam removes impurities such as oxidation or functional layers which hinder the joining process.

- The laser evaporates the undesirable layers using very high peak pulse power, in a very gentle, non-contact manner.

- Compared to CO2 lasers which still leave a thin layer (e.g. 5 µm of paint) behind during cleaning, solid-state lasers are able to process surfaces in an even more targeted manner. The laser pulses have virtually no thermal effect on the workpiece surface; this prevents distortion or damage/changes to the material.

- The ablated material can be easily and directly removed by means of an optional exhaust system that is integrated into the respective system.

- Specific laser parameter settings also allow the laser to be used to structure component surfaces in order to provide better grip for adhesive areas and frictional and form-locking connections, as well as to apply component markings (e.g. tracking codes).