The particularly powerful short-pulse lasers of the TruMicro series 7000 can ablate layers quickly and across large surfaces, drill or cut with high throughput. With pulse energies of up to 100 mJ, they can achieve tremendous decoating rates with an excellent level of efficiency. You can vary the pulse repetition rate of the laser while maintaining an even pulse duration, optimising your machining processes. Large surfaces can be ablated particularly efficiently through the use of scanners.

Specialist for large surfaces

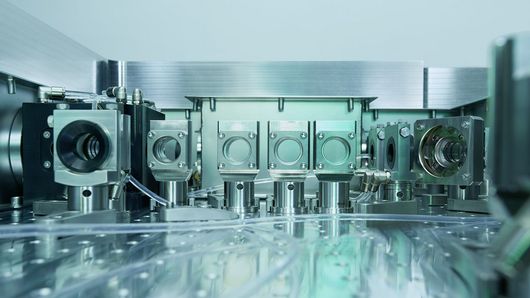

The high-performance short-pulse lasers from the TruMicro Series 7000 are based on disk laser technology and combine short pulses with high pulse energies, even with high frequencies. The lasers are therefore ideal for large-scale and quick cleaning, ablation, or structuring with maximum throughput.

Flexible beam guidance makes the lasers easy to integrate into your manufacturing system, and they are fully compatible with our PFO series of scanner optics, which enables precise processing of large surfaces.

The ideal combination for your microprocessing requirements.

Clean or anneal large components and identify their optimal operating point.

The internal power regulation provides the full pulse energy for your process.

The configurable power distribution allows for optimal adaptation to your application.

Decoating sensitive copper hairpins on electric motors

The sensitive copper of electric motor hairpins is protected against oxidation and damage by a layer paint. To prepare the pins for welding, the layer of paint is selectively removed using a short-pulse laser without damaging the underlying copper. The results of the process are more precise and faster than those of mechanical stripping processes. The hairpins are then precisely welded for maximum conductivity.

Plastic-metal hybrid connection

Automobile manufacturers are increasingly turning to lightweight design in order to reduce the consumption and CO2 emissions of their vehicles. Hybrid metal-plastic connections are playing an increasingly important role here, since they combine the high strength and rigidity of metals with the low weight and great design freedom of plastic, for example. The high-performance nanosecond lasers of the TruMicro Series combine metal and plastic perfectly and without any additional materials, such as screws, rivets or adhesives.

Edge deletion of thin-film solar modules

In order to protect thin-film solar modules against corrosion and long-term short circuits, the layer system at the edge of the module is removed and then laminated. In this application, the laser penetrates the glass and splits off the layer system from the carrier material, without causing any cracks or fusing on the glass. In comparison to conventional sandblasting, there are no costs for the blasting medium or its supply. Furthermore, the excellent process properties ensure extremely high decoating rates.

Welding preparation of AlSi-coated steel sheets

The nanosecond lasers of the TruMicro Series 7000 are ideal for the efficient ablation of aluminium-silicon coats – without changing the basic material. In the automotive industry in particular, steels are coated with aluminium-silicon (AlSi) as an anti-corrosion agent. For perfect welding results, this coating must be removed in the welding seam area.

Cleaning and paint removal with short-pulse laser

The short-pulse laser enables paints, residual adhesives, or oxide films to be partially or fully removed from surfaces without damaging the basic material. The laser meets user requirements in terms of edge and ablation quality in particular, however the laser process also competes with conventional processes when it comes to cost efficiency.

|

TruMicro 7060

|

TruMicro 7070

|

|

|---|---|---|

| Laser parameters | ||

| Average output power | 1000 W | 2000 W |

| Beam quality | 10 mm▪mrad , depends on the optical laser cable that is used | 10 mm▪mrad , dependent on the laser light cable used |

| Wavelength | 1030 nm | 1030 nm |

| Pulse duration | 30 ns | 30 ns |

| Maximum pulse energy | 100 mJ | 100 mJ |

| Minimum repetition rate | 5 kHz | 5 kHz |

| Maximum repetition rate | 100 kHz | 250 kHz |

| Minimum laser light cable diameter | 300 μm | 300 μm |

| Structural design | ||

| Dimensions for basic device size (W x H x D) | 1340 mm x 1430 mm x 725 mm | 1340 mm x 1430 mm x 725 mm |

| Dimensions for extended device size (W x H x D) | 1340 mm x 1475 mm x 1040 mm | 1340 mm x 1475 mm x 1040 mm |

The technical data of all product versions as a download.

TruControl

TruControl is the quick and easy-to-use control for TRUMPF solid-state lasers. It regulates the laser power in real time in order to deliver reproducible results. TruControl manages, controls and visualises the interface configuration. You benefit from a uniform control architecture across all laser technologies. The lasers have interfaces to control intelligent TRUMPF optics, such as monitored CFO focusing optics or PFO scanner optics. You can program the processing optics easily using the laser control system. With the Teleservice from TRUMPF you will also receive remote support in seconds. This will allow you to avoid service calls or be as prepared as possible and increase the availability of the laser device.

With added options, you can work even more efficiently and with more process reliability with the high-performance nanosecond lasers of the TruMicro Series 7000.

There are many different options for the beam guidance that will enable you to plan flexibly with your laser. The plug & play optical laser cables can be easily connected to different work stations. Here, you choose the number of fibre outlets up to a total of four. The laser power is regulated for each outlet. This allows multiple work stations to operate simultaneously with split laser power or one after the other with full laser power. With the modular system, you can even retrofit this splitting functionality.

With the laser network, you can connect one or more lasers with up to four work stations in each case. In the process, your laser either splits its power to multiple stations, or it supplies them by turns with full power. This will enable you to combine different applications with one another.

Intelligent optics can be synchronised with your laser via a dedicated interface. This will allow you, for example, to use the CFO focusing optics or PFO scanner optics optimally for your purposes. You can program the processing optics easily using the laser control system. You do not need any additional PCs or control systems.

In the event of a fault, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases the fault can be remedied directly in this way, or the configuration of the laser can be modified in a way that permits you to continue manufacturing until the spare part arrives.

TRUMPF offers you all the components you need for beam guidance from the laser to the workpiece. This also applies for various focusing optics which have proven themselves to be precise and reliable over many years of industrial use. The optics can be easily integrated – both in stand-alone processing stations as well as in complete production lines. The modular structure enables the optics to be continually adapted to the laser types as well as the different processing situations.

Focusing optics

Whether for welding, cutting, ablating, heating up or drilling: with robust fixed optics from TRUMPF you can attain high-quality process results!

Programmable focusing optics

The ideal optics for remote processing

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Find the right pulsed laser for you!

Use the product finder to discover which pulsed laser is best suited to your application!