There are two application areas when cutting battery foils. On the one hand - "slitting": continuous lengthwise cutting or separation of the mother coil (electrode foil coated on one or both sides). It is cut into several subcoils (parts). The laser is in a fixed position, the foil runs continuously through the laser beam from roll to roll.

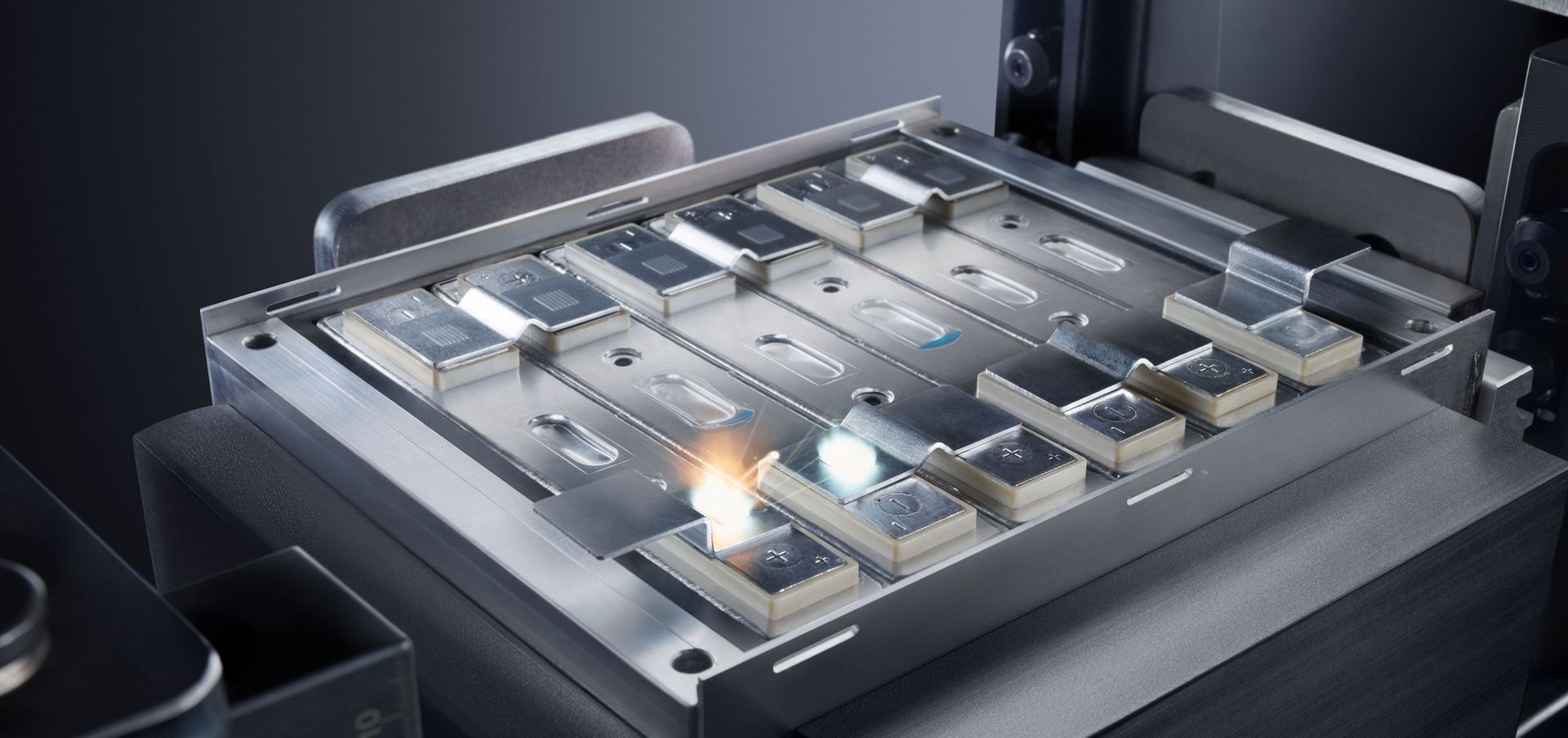

The second application area is contour cutting of the coated electrode foil. In this case, electrodes (anodes/cathodes) are cut from the coil in the required shape and quantity. In combination with scanner optics and moving axes or further lasers to increase the scanning area, the laser cuts the electrode foil to the desired shape. During contour cutting, the speed is above 1m/s. The foil thickness (foil and two-sided coating with active material) is between 100 and 250 µm. For both applications, TRUMPF lasers satisfy the high demands of battery manufacturers in terms of cutting speed, heat-affected zone, burr formation as well as particle or spatter formation.