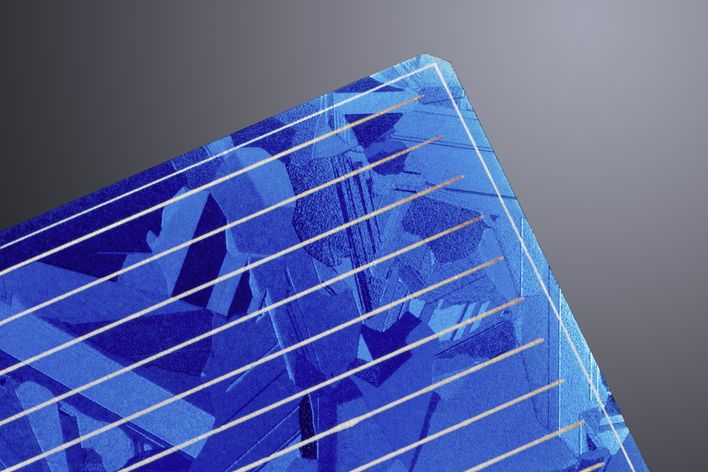

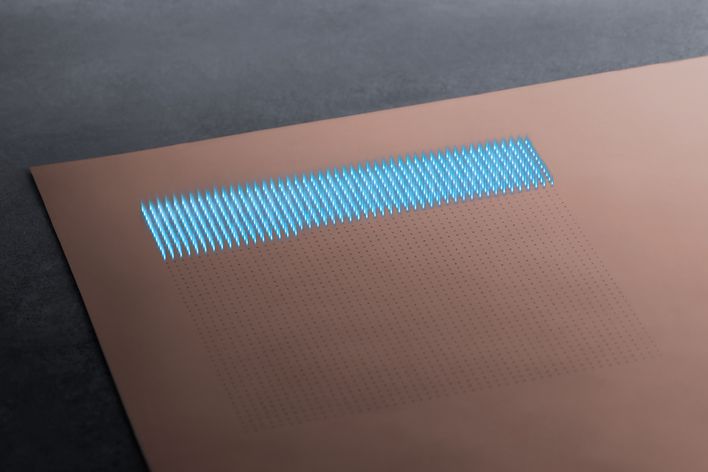

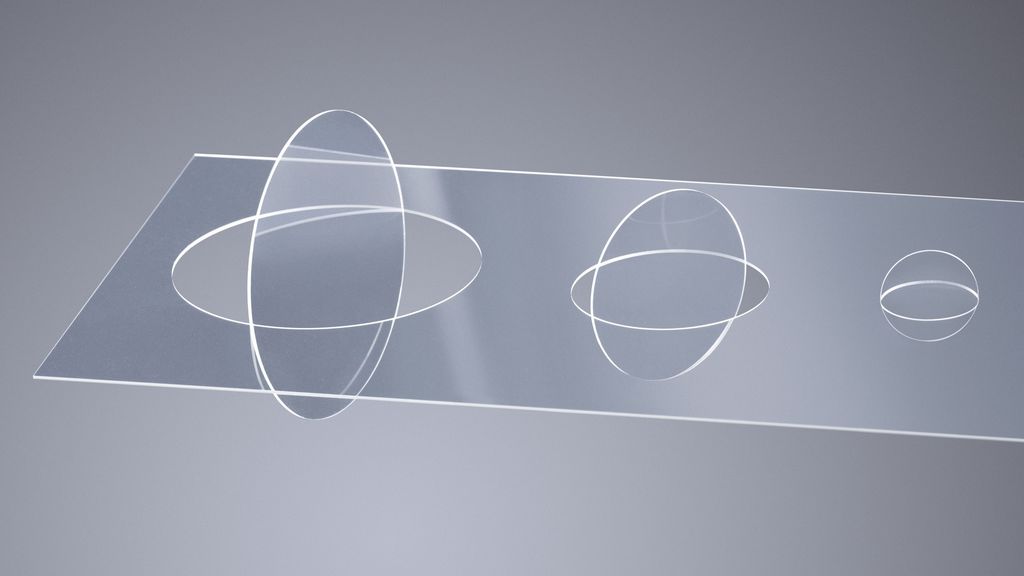

For a long time, the notion of performing structuring and ablation work using solid-state lasers was practically unknown. It is only since micro-processing has been on everyone's mind that these methods are increasingly moving into the spotlight. During laser structuring and laser ablation, workpieces are processed in small and tiny dimensions.

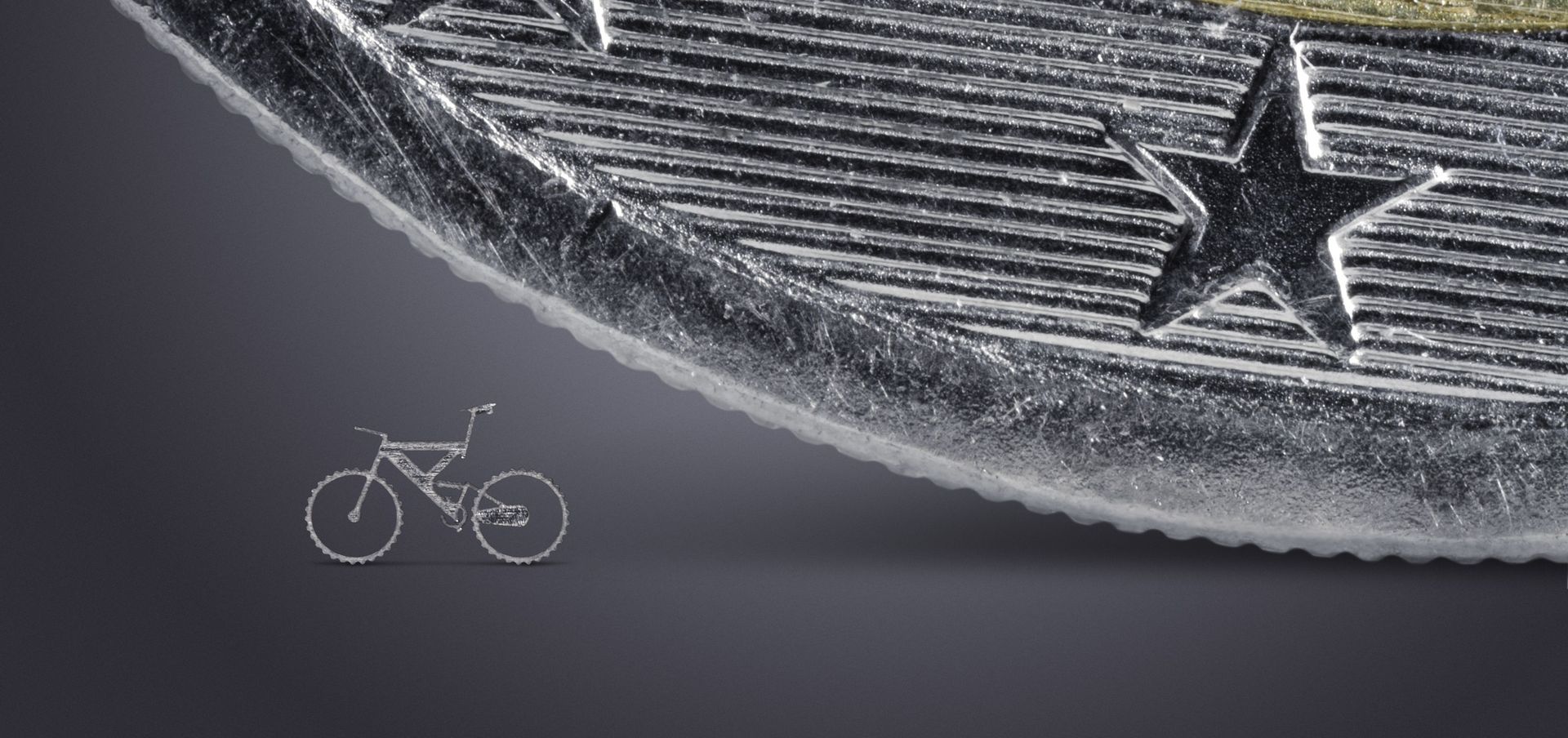

In terms of the methods involved, structuring and ablation are closely related. Short laser pulses with very high pulse power generate such high energy densities that the material usually evaporates immediately (sublimates). This method creates only a minimal melt. Each laser pulse produces a small depression, typically measuring approx. 10 micrometers in diameter and just a few micrometers in depth.