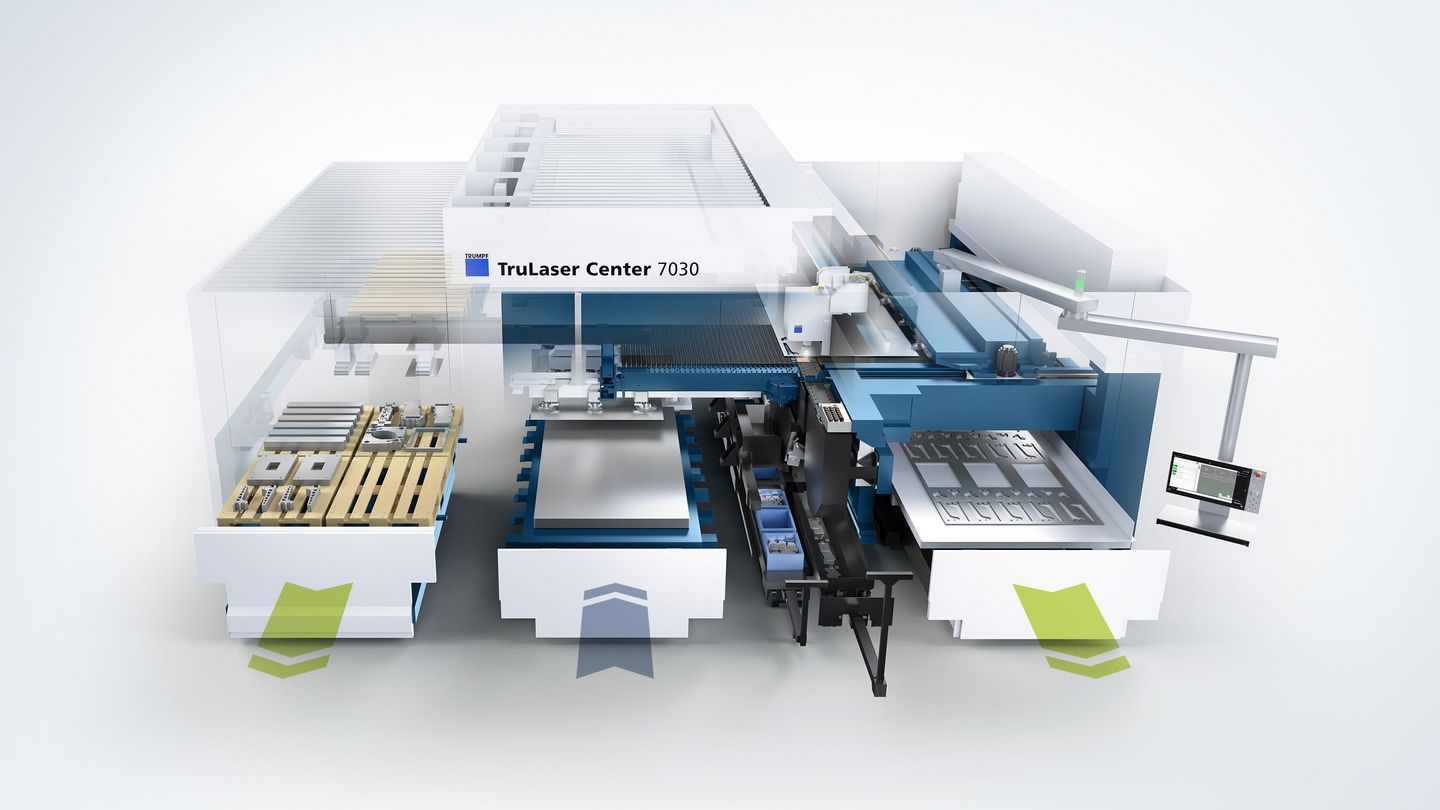

In contrast to traditional 2D laser processing machines, on the TruLaser Center 7030 both the cutting head and the sheet metal move. The additional axis on the cutting head enables the machine to achieve first-rate cutting dynamics. This means that you can cut corners and complex contours at high speeds. This highly dynamic combination makes full use of the high feed rates of the solid-state laser.

The TruLaser Center 7030 – leaves behind the fundamental principle of laser processing

High process reliability or high productivity? The TruLaser Center 7030 resolves this classic decision conflict in laser processing for the very first time. The fully automatic machine takes care of your entire laser processing operations – from the drawing to the sorted part. The machine guarantees reliability through its integrated intelligence, such as the SmartGate, SmartLift, and SortMaster Speed. The novel machine concept with its additional axis and higher-level axis movements provide speed and revolutionary productivity. The perfect interaction of the components makes the machine incomparably economic.

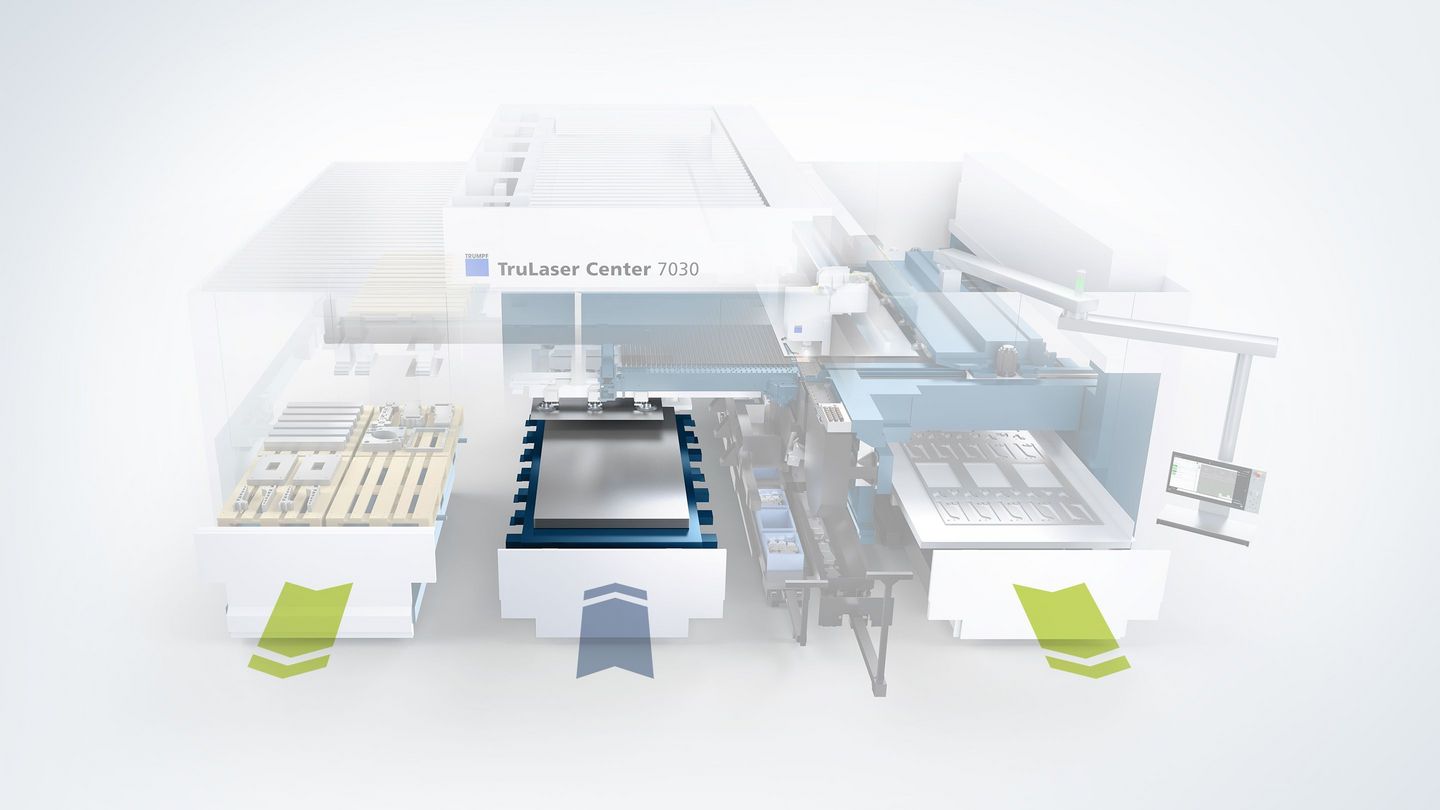

Profitable overall system

Whoever wants to optimize costs with laser cutting must take the whole process into consideration. The TruLaser Center 7030 was created with this objective: it safely and independently takes on all processes related to laser cutting. The advantage for you: Your throughput time and processing costs will be drastically reduced. You get maximum profitability from your laser machining process – from the drawing to the sorted part. The machine takes over monotonous and tedious tasks, saving you costs and time simultaneously.

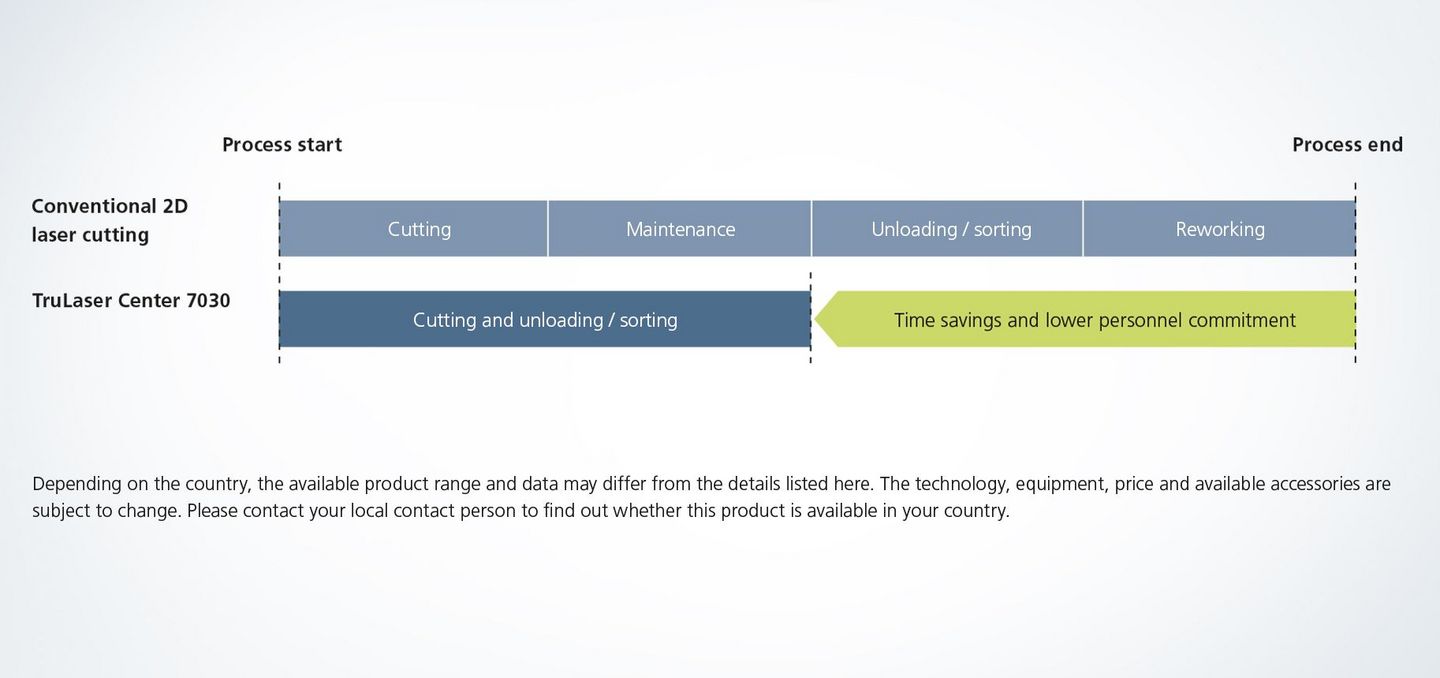

A comparison of process steps

The result is that the TruLaser Center 7030 takes on all processes related to laser cutting reliably and independently – which significantly lowers your sheet metal processing costs.