Economic reliable machine

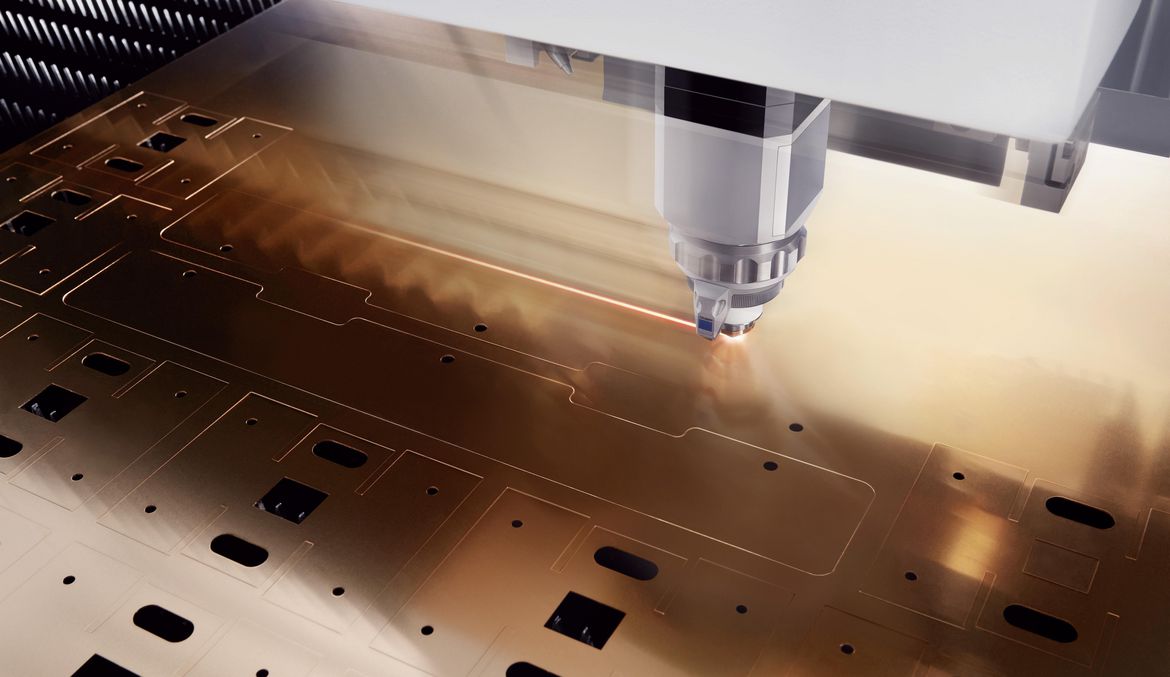

The TruLaser Series 1000 fiber Basic Edition is the ideal introduction to the world of high-quality laser cutting. It is equipped with a TruFiber laser for cutting a wide range of sheet thicknesses. The intuitive programming system makes it possible to start production quickly. In addition, we are always on hand to lend our support: You can count on our experienced and competent service team to answer all your questions regarding maintenance and applications.

Thanks to the intuitive design and the TecZone software with integrated cutting data, you can get started right away.

High-quality components and production according to TRUMPF Quality Standard guarantee safe operation.

Stable results thanks to optimal machine design.

You can rely on TRUMPF Remote Service, fast technical support and professional training offers

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

![[Translate to th_TH:] TruLaser Series 1000 Basic Edition](/filestorage/TRUMPF_Processed/_processed_/6/4/csm_TruLaser-1030-fiber-L99-Basic-Edition-product-picture_7807ad35f6_79fe998607.jpg)

![[Translate to th_TH:] TruLaser Series 1000 Basic Edition](/filestorage/TRUMPF_Processed/_processed_/6/4/csm_TruLaser-1030-fiber-L99-Basic-Edition-product-picture_7807ad35f6_332f7c69a4.jpg)