The High Power Seed Module (HPSM) consists of two seed lasers – which generate output pulses of just a few watts, as well as of a variety of active and passive optical components, which form the laser beam and ensure an optimal pulse duration. An initial amplifier is used to pre-amplify the light to a magnitude of 100 W. The seed lasers have protection mechanisms that provide optimum protection against back-reflections, which significantly increases the stability of the entire system and enables the required continuous EUV power to be achieved.

TRUMPF Laser Amplifier

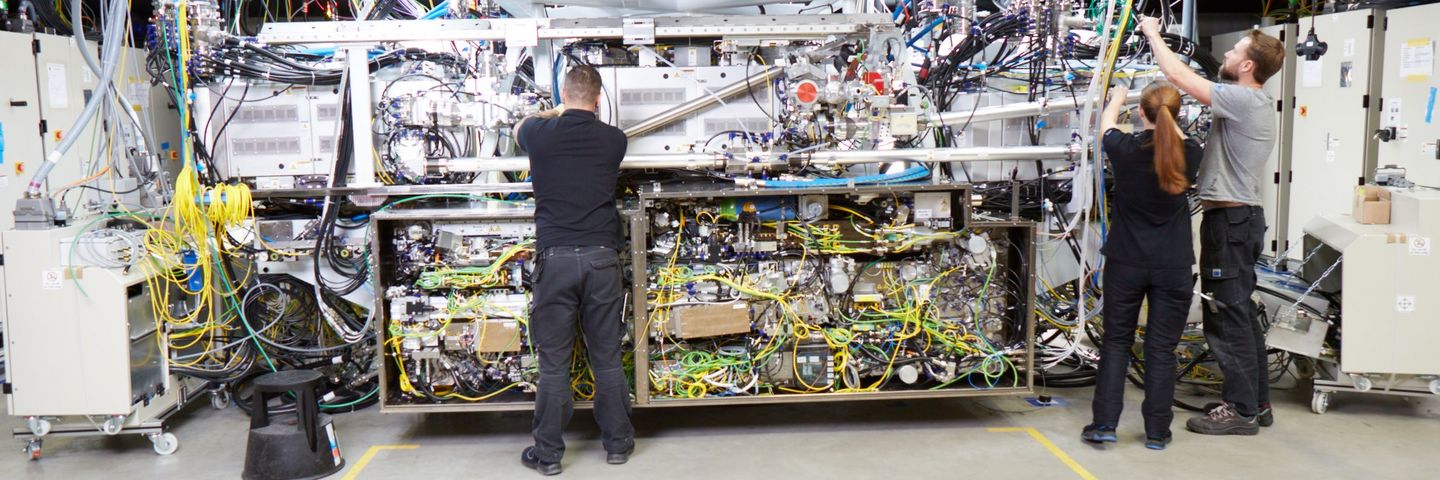

With its laser pulse, it provides the starting point for the future production of microchips.

EUV lithography – enabling progress in the digital era

EUV lithography wins the race for the microchip production method of the future. For many years, the semi-conductor industry has been looking for a cost-efficient and mass-production process to expose even smaller structures on silicon wafers. ASML, Zeiss, and TRUMPF joined forces to develop a technology to produce extreme ultraviolet (EUV) light with a wavelength of 13.5 nanometers for industrial use: In a vacuum chamber, a droplet generator shoots 50,000 tiny tin droplets per second. Each of these droplets is hit by one of the 50,000 laser pulses and turned into plasma. This produces EUV light, which is directed by a mirror onto the wafers to be exposed. The laser pulse for the plasma radiation is provided by a pulsable CO2 laser system developed by TRUMPF – the TRUMPF Laser Amplifier.

The TRUMPF Laser Amplifier sequentially amplifies a laser pulse by more than 10,000 times.

By emitting a pre pulse as well as a main pulse, the full power of the Laser Amplifier can be transferred to the tin droplet.

The basis of the high-power laser system is a CO2 laser with continuous wave operation. TRUMPF is thus creating a new application for the technology.

Over their years of close collaboration, TRUMPF, ASML, and ZEISS have brought EUV technology to industrial maturity.