A true all-around solution

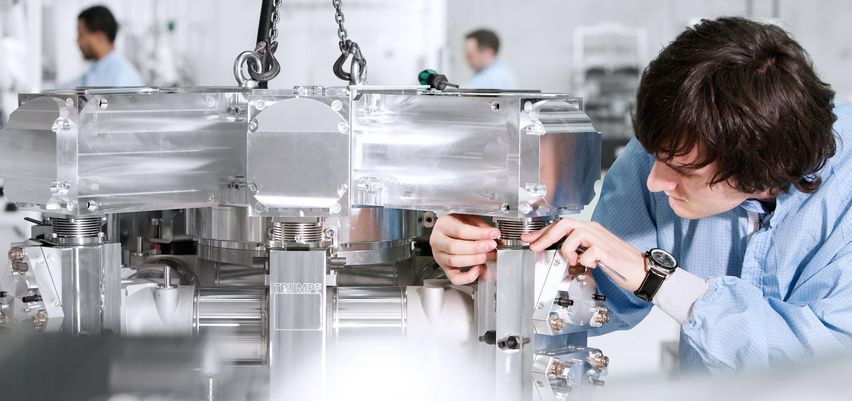

The TRUMPF CO2 lasers in the TruFlow series have been used in industry as universal standard tools in material processing for years. The flow lasers cut, weld, and treat the surfaces of two- or three-dimensional parts in a reliable and cost-effective way. The wavelength of 10.6 µm and the large power spectrum from 2 to 20 kW give a great degree of freedom in the selection of material type and thickness. TruFlow lasers not only process metal, but also organic materials, compound materials, and glass.

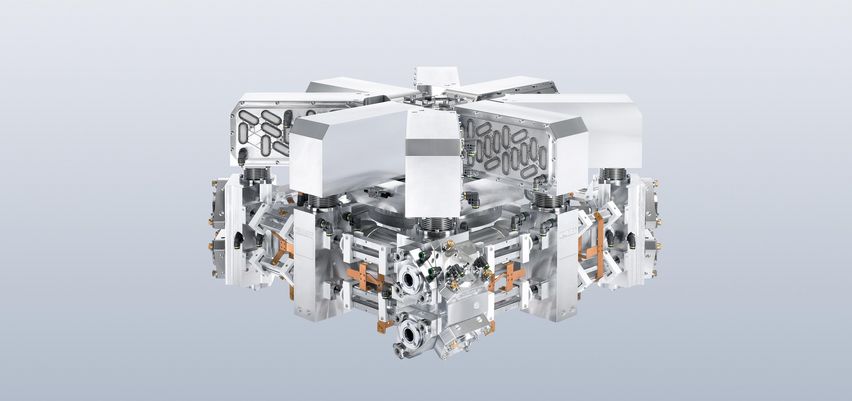

Due to its square design, the resonator is mechanically robust and temperature-resistant.

The cooling concept and intelligent energy management make TruFlow lasers the most energy-efficient lasers of their kind.

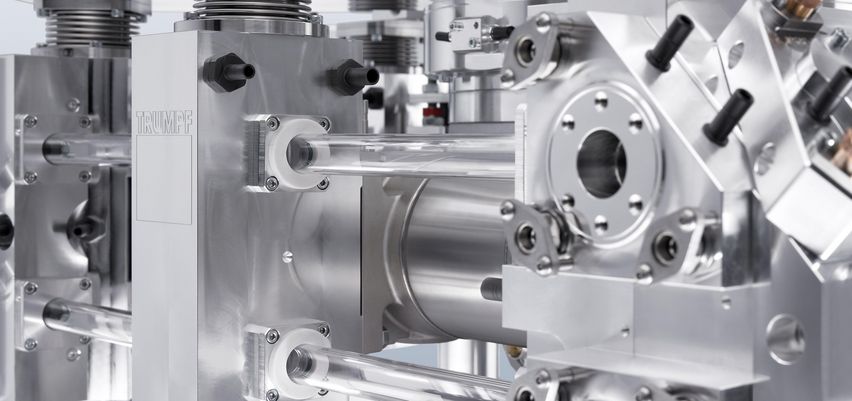

Wear-free laser operation with respect to gas circulation and RF excitation.

Optimally formed laser light using integrated and encapsulated beam guidance.

Continuous monitoring of temperature and degree of contamination.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- Other optics configurations are available on request.